I was so surprised to come across this site and see there's a huge community revolving around Plasma Cam.

I've got 30+ years experience Fabricating Metals, and finally made a CNC Plasma purchase this year. I'm a cad guy from way back, and hope to contribute something to the community when I get this machine figured out.

Figuring the Baileigh name has been around for as long as I can remember, I threw down the cash and bought a

Baileigh PT-105HD-W CNC PLASMA TABLE with a Thermal Dynamics A120 Plasma Cutter.

The setup and Wiring was the easy part.... The lack of information in the manuals was quite a surprise though. So, after a few hours digging through the web and searching out definitions of terminology and functions I was able to get the machine to make a cut.

As for the THC on the Torch Z axis...It's still a mystery. Doesn't seem to want to respond to setting changes of voltage (to get tip closer to the material).

Tried cutting with a 40, and 60 amp tip setup and no height difference is being seen. So far the closest I can get the tip while cutting is about 3/16" to the base metal, which is leaving a steep bevel, although the dross is pretty minimal, I know it can be improved.

I'm open to any suggestions if anyone has any input on what I'm describing.

I Hope to make progress cutting soon.

Cheers!

Hi All!

-

Eartheniron

- 1/2 Star Member

- Posts: 9

- Joined: Thu Jan 23, 2020 9:57 am

- acourtjester

- 6 Star Elite Contributing Member

- Posts: 7792

- Joined: Sat Jun 02, 2012 6:04 pm

- Location: Pensacola, Fla

Re: Hi All!

Welcome aboard with many of us the THC can be a mystery so you can see it a little clearer this is how it works. The arc voltage is different with metal thickness, type of metal amps and size of tip. I don't know if your Thermal Dynamics has a chart with this info or not, Hypertherm does. The THC is controlled by the arc voltage, so you need to know what arc voltage to set in the THC for it to maintain the correct cutting height. Here is a video I made to help you develop a chart for you table equipment. This is based on the equipment I use but the concept is the same. There also may be setting in your software to enable the THC, or a system failure. Does you unit have a readout of the arc voltage as it cuts, it should fluctuate a small amount the Z should also move up and down with the fluctuation.

https://youtu.be/EyZJVMtzKzY

https://youtu.be/EyZJVMtzKzY

DIY 4X4 Plasma/Router Table

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

-

Eartheniron

- 1/2 Star Member

- Posts: 9

- Joined: Thu Jan 23, 2020 9:57 am

Re: Hi All!

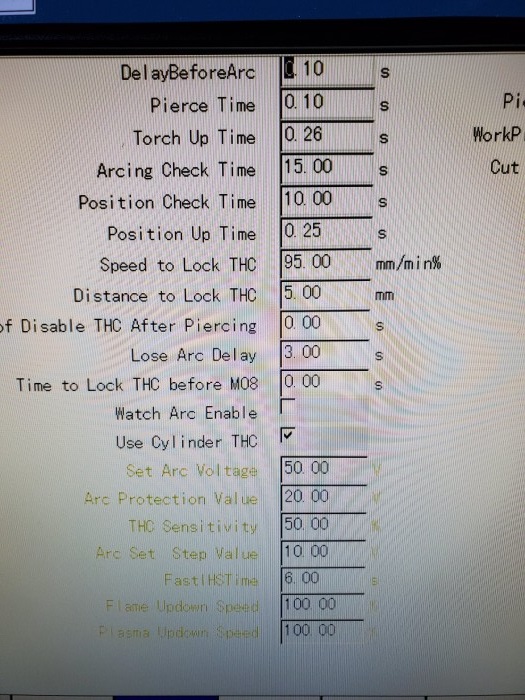

Thanks for the feedback. I've taken a screenshot of the set up I'm using to cut some 16 gauge hot roll. I've played with just about every setting in this menu incrementally and I cannot seem to get The torch hide controller to respond to anything. Please have a look at my settings menu and tell me what you see that is completely off base.

Thanks!

Thanks!

- acourtjester

- 6 Star Elite Contributing Member

- Posts: 7792

- Joined: Sat Jun 02, 2012 6:04 pm

- Location: Pensacola, Fla

Re: Hi All!

Your software is not one I have used so not help sorry.

But I would say the THC sensitivity is way to high you need from .5 to 1.0 volts and set arc voltage should be set for the TD unit you have

But I would say the THC sensitivity is way to high you need from .5 to 1.0 volts and set arc voltage should be set for the TD unit you have

DIY 4X4 Plasma/Router Table

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

-

Eartheniron

- 1/2 Star Member

- Posts: 9

- Joined: Thu Jan 23, 2020 9:57 am

Re: Hi All!

Thanks for your input. I'll run some more trials tomorrow and see if that makes a difference.

-

Eartheniron

- 1/2 Star Member

- Posts: 9

- Joined: Thu Jan 23, 2020 9:57 am

Re: Hi All!

So just an update... with all of the subtle changes I made to the cut profile option menu, I was able to cut 1/4" mild steel plate which I believe is a very acceptable cut. However, up to this point I still have no control or movement of the torch in the x axis. Also the Voltage feedback isn't registering on the screen either...The 16 gauge steel cut pretty good, but as the sheet warps, the Torch won't compensate, or sense the base metal height change, thus collides, and stalls...Either there's a hidden check box disabling this feature that I can't find, or a software glitch, or a setting on this menu that is beyond my understanding, or description in the so called manual. I am bewildered as the why a company would sell a piece of equipment with crap for an explanatory manual. A couple of simple cut profiles for maybe three thicknesses of common steel materials would be a Golden Ticket and probably a lifesaver for the amount of Tech Support calls I can imagine they recieve... and the patient wait for tech support call back goes on.

- acourtjester

- 6 Star Elite Contributing Member

- Posts: 7792

- Joined: Sat Jun 02, 2012 6:04 pm

- Location: Pensacola, Fla

Re: Hi All!

Ok I cannot comment on their software but with most there is a input signal that tell the controller arc OK (on) and to move the torch up and torch down, and an enable for the THC so the software knows to look for these signals. These signal require a connection to the Plasma unit, this may be the reason you are not seeing the arc voltage. I agree there seems to be some really poor companies doing business, this is why many newbies ask about the tables they are looking at or who to avoid.

DIY 4X4 Plasma/Router Table

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

-

Eartheniron

- 1/2 Star Member

- Posts: 9

- Joined: Thu Jan 23, 2020 9:57 am

Re: Hi All!

Hi Jester,

We're up and running...After a voltage test with the tech support, they said the voltage divider was faulty, so they sent me a new one....

we wired it up and had nothing change, so we ended up chasing down a reversed wire polarity in the factory harness.

And now we have correct reading voltage and a torch that reacts to the elevation changes in the surface material.

It's been a long road, but were now going to get creative!

Dave

We're up and running...After a voltage test with the tech support, they said the voltage divider was faulty, so they sent me a new one....

we wired it up and had nothing change, so we ended up chasing down a reversed wire polarity in the factory harness.

And now we have correct reading voltage and a torch that reacts to the elevation changes in the surface material.

It's been a long road, but were now going to get creative!

Dave

- acourtjester

- 6 Star Elite Contributing Member

- Posts: 7792

- Joined: Sat Jun 02, 2012 6:04 pm

- Location: Pensacola, Fla

Re: Hi All!

Very good, finding a problem sometimes helps the learning process, no longer looking for a witch doctor to shake a stick at it.

DIY 4X4 Plasma/Router Table

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT

Hypertherm PM65 Machine Torch

Drag Knife and Scribe

Miller Mig welder

13" metal lathe

Small Mill

Everlast PowerTig 255 EXT