Diy 18" rotary on a langmuir crossfire 2x2

-

Jgorm

- 1 Star Member

- Posts: 22

- Joined: Sat Jan 11, 2020 11:13 am

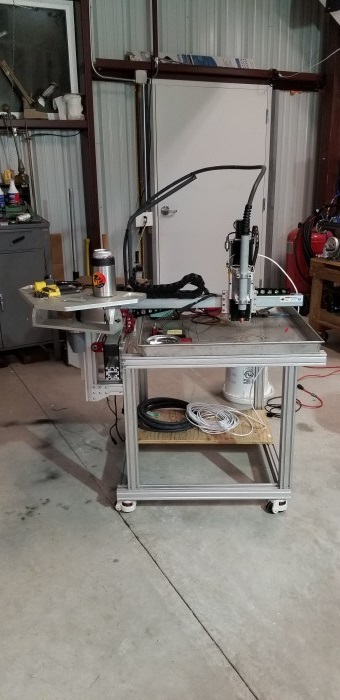

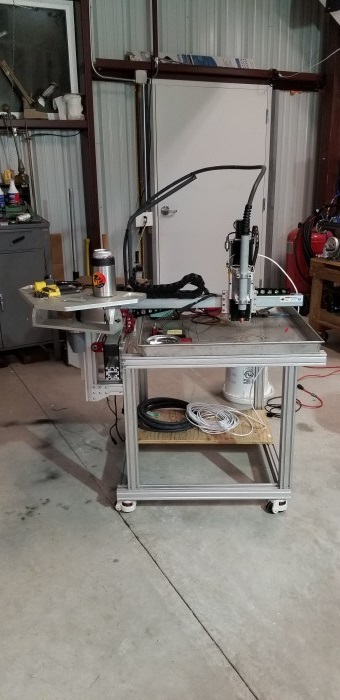

Diy 18" rotary on a langmuir crossfire 2x2

I have a need to make some prototypes on 2'x18" SS 10g cylinders. I'm totally new to cnc so i bought the crossfire to get started. I'll need thc because the cylinders are not perfectly round. I just got the ess and tmc3in1 and my z axis with magnetic breakaway and floating head on order. I'm building my electronics case out of an old computer case. I used some cake pans from Walmart to mount an automotive air filter on the front.

Next steps

And the stand

You currently do not have access to download this file.

To gain download access for DXF, SVG & other files Click Here

-

AREA

- 3 Star Member

- Posts: 378

- Joined: Thu Jul 19, 2012 3:36 am

Re: Diy 18" rotary on a langmuir crossfire 2x2

Very interesting! Looking forward to seeing your progress

DIY 2x2 table

Everlast 82i

Everlast 82i

-

Jgorm

- 1 Star Member

- Posts: 22

- Joined: Sat Jan 11, 2020 11:13 am

Re: Diy 18" rotary on a langmuir crossfire 2x2

I started milling 8020 last night. I got the top frame done but forgot to take pictures. I made a video because i didn't find any examples on YouTube. 8020 takes far more time than making a frame out of steel and welding it! I had free 8020 and i like the adjustability of it. Hopefully it's worth it! I need to buy $100+ worth of those little fittings.

https://youtu.be/rV1kvw8HysE

https://youtu.be/rV1kvw8HysE

-

Jgorm

- 1 Star Member

- Posts: 22

- Joined: Sat Jan 11, 2020 11:13 am

Re: Diy 18" rotary on a langmuir crossfire 2x2

Got the frame made

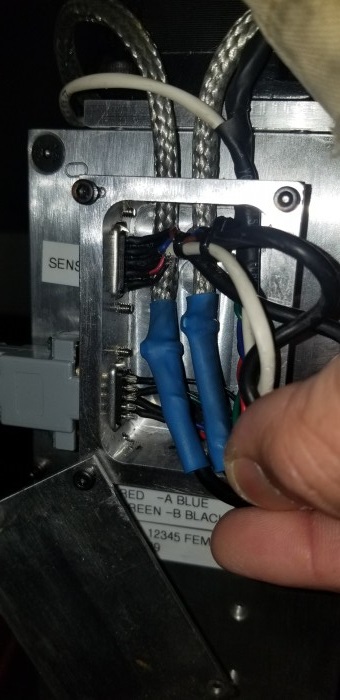

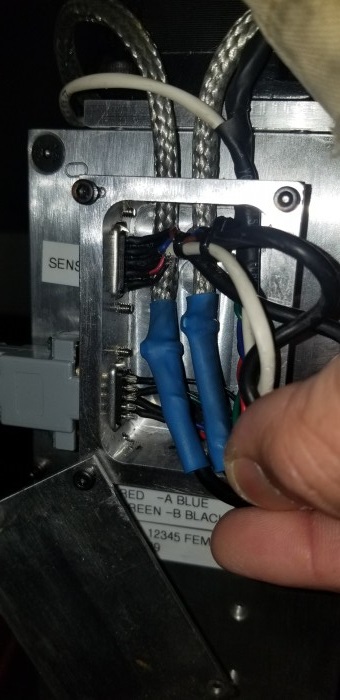

Working on the z axis

Shrink and soldered with a modification to the switch lever to get it to click with less movement

Shrink and soldered with a modification to the switch lever to get it to click with less movement

You currently do not have access to download this file.

To gain download access for DXF, SVG & other files Click Here

-

AREA

- 3 Star Member

- Posts: 378

- Joined: Thu Jul 19, 2012 3:36 am

Re: Diy 18" rotary on a langmuir crossfire 2x2

Wow man loookin good! That Z axis is super sweet but looks like it will crush your gantry if its on the far end!! Beefy!!

DIY 2x2 table

Everlast 82i

Everlast 82i

-

Jgorm

- 1 Star Member

- Posts: 22

- Joined: Sat Jan 11, 2020 11:13 am

Re: Diy 18" rotary on a langmuir crossfire 2x2

Haha yeah. I get about 0.25" deflection at the end of x when i balance it. I'm not too concerned because I'll rarely be out there. My rotary axis will be parallel to the y axis so the defection should be consistent during cutting with the z axis stationary on the x axis. If I'm flat cutting large parts at the end of the x hopefully the thc does it's job. I'm hoping to make some prototypes that are better than my inadequate hand cutting. If the businesses takes off I'll add a supported gantry on linear rails. That's the beauty of 8020 frames.AREA wrote: Mon Jan 27, 2020 10:27 am Wow man loookin good! That Z axis is super sweet but looks like it will crush your gantry if its on the far end!! Beefy!!

-

Jgorm

- 1 Star Member

- Posts: 22

- Joined: Sat Jan 11, 2020 11:13 am

Re: Diy 18" rotary on a langmuir crossfire 2x2

The stupid mounting plate was kicking my ass. Got too many hours into it. I milled clearance for the bearings and screws. Drilled and countersunk mounting screws. Cut my only tapered screws of that size to the right length. I just need to tap 4 or 6 holes to mount the mounting plate. I had to machine slots on that too to clear the screws on the bearings for the x axis.

I scored all these machine screws for free but still didn't have the ones i needed!

Home made portaband stand cuts screws without buggering the threads.

Getting closer.

Hopefully i can finish mounting the z this week, but i have a pretty massive project going on at my river house this weekend that i need to prepare for.

You currently do not have access to download this file.

To gain download access for DXF, SVG & other files Click Here

-

robertspark

- 4.5 Star Elite Contributing Member

- Posts: 1831

- Joined: Mon Jun 12, 2017 6:43 pm

Re: Diy 18" rotary on a langmuir crossfire 2x2

Also consider wobble.... (More technically jolt / jerk) which occurs due to axis acceleration and deceleration

Worth a shot I guess... But that is why most plasma cutters run a slaved axis X + X' or Y + Y' to provide axis stability to the gantry when the z axis is moving up and down and the carriage is moving back and forth.

Imo I'd sell the crossfire as a working machine and build one that meets your needs...

Remember the lateral movement with 1g of acceleration will mean that something weighing 5lb will put a force of 5lb laterally.... Or 0.5g of acceleration will put a force of 2.5lb laterally.... Then consider torque / leverage (force X distance)..... 2.5lb X 2 ft = 5ftlb of torque......

Build it light! And it will be able to move fast.... And plasma is all about fast acceleration to maintain constant velocity with changes in direction or blended axis motion

Worth a shot I guess... But that is why most plasma cutters run a slaved axis X + X' or Y + Y' to provide axis stability to the gantry when the z axis is moving up and down and the carriage is moving back and forth.

Imo I'd sell the crossfire as a working machine and build one that meets your needs...

Remember the lateral movement with 1g of acceleration will mean that something weighing 5lb will put a force of 5lb laterally.... Or 0.5g of acceleration will put a force of 2.5lb laterally.... Then consider torque / leverage (force X distance)..... 2.5lb X 2 ft = 5ftlb of torque......

Build it light! And it will be able to move fast.... And plasma is all about fast acceleration to maintain constant velocity with changes in direction or blended axis motion

-

Jgorm

- 1 Star Member

- Posts: 22

- Joined: Sat Jan 11, 2020 11:13 am

Re: Diy 18" rotary on a langmuir crossfire 2x2

Thanks for the tips. Right now cut quality isn't a concern at all so i can slow it down as needed. I have 0 experience with cnc anything so for 1000 bucks the crossfire gave me a headstart. I do plan on selling it as a kit eventually. I'm about 8k into this project already. I got a quote for a proper gantry xyz steppers and electronics and it was $9800. I'm 2500 into this cncand can probably sell the crossfire for 800. Hopefully it turns into a successful business and i can quit managing a chemistry lab and build servo cncs or laser cutters!

-

robertspark

- 4.5 Star Elite Contributing Member

- Posts: 1831

- Joined: Mon Jun 12, 2017 6:43 pm

Re: Diy 18" rotary on a langmuir crossfire 2x2

Slowing the cut down is not always a good thing..... Kerf gets wider... THC voltage rises... THC lowers....

What do you intend to cut (roughly) thicknesses plus diameter ?

What are you going to cut it with (machine plus model / amperage rating)

What do you intend to cut (roughly) thicknesses plus diameter ?

What are you going to cut it with (machine plus model / amperage rating)

-

Jgorm

- 1 Star Member

- Posts: 22

- Joined: Sat Jan 11, 2020 11:13 am

Re: Diy 18" rotary on a langmuir crossfire 2x2

18" diameter 10g stainless with a PM65.robertspark wrote: Tue Jan 28, 2020 4:44 pm Slowing the cut down is not always a good thing..... Kerf gets wider... THC voltage rises... THC lowers....

What do you intend to cut (roughly) thicknesses plus diameter ?

What are you going to cut it with (machine plus model / amperage rating)

-

Jgorm

- 1 Star Member

- Posts: 22

- Joined: Sat Jan 11, 2020 11:13 am

Re: Diy 18" rotary on a langmuir crossfire 2x2

I got the z axis mounted and wires soldered up. Also mounted a laptop stand. Working on getting the ess and thc wired up, hopefully today. Quarantine -> progress!

-

cuttinparts

- 3 Star Elite Contributing Member

- Posts: 439

- Joined: Tue Sep 30, 2008 3:40 pm

Re: Diy 18" rotary on a langmuir crossfire 2x2

Looks awesome man! Way to go, looking forward to seeing your finished setup

-

Jgorm

- 1 Star Member

- Posts: 22

- Joined: Sat Jan 11, 2020 11:13 am

Re: Diy 18" rotary on a langmuir crossfire 2x2

I gave up on the quarantine thing about 6 weeks ago and didn't every weekend having fun at the river and visiting family, but i spent yesterday working on this. I have x y and z Control but i haven't checked to see how accurate the movement is. It works better than i expected with the cantilevered x axis. I still have to wire up there thc and limit switches. After that I'll cut the brackets for the a axis.

Download DXF/SVG

Download DXF/SVG