Sheetcam and THC

-

mkingaz

- 2 Star Member

- Posts: 58

- Joined: Wed Jun 05, 2019 7:32 pm

- Location: Glendale Arizona

Sheetcam and THC

I have a premier plasma 4x8 flat deck, running a xp45 with SD Promo TCH. I'm new to plasma cutting and having an issues. A few months bank I was wiring up the THC and after I could read all the volts and settings on the unit I could not get my table to work correctly for days. I called Jake the owner after a few days of working on it at a total loss and he actually came to my house and fixed the issue. It was determined that sheetcam had a software issue and deleted from the computer and re-installed it and all was good.

I thought anyways, so I have notice cutting thin metal 16 ga, that it seems like when the torch started it would work correctly. Take off head to first cut, drop to table, lift and start cutting and is lowered or lifted as it should. However, I notice that almost every other cut it would take off to the cut by dragging. I think I was getting away with cutting small things because it was so thin. Just my guess, wish I knew more now on these tables.

Today, I was hoping to cut a 1/4 HR sheet and cut out a welding table found here on the site. This is when things got magnified and I basically have screwed up a 4x4 sheet. I think I can still save it but 4 holes are a loss.

My thought is remove Sheetcam again and reload it. Does this sound like a good option?

I love this site and all the support, Thank you to all the educated helpful members.

I thought anyways, so I have notice cutting thin metal 16 ga, that it seems like when the torch started it would work correctly. Take off head to first cut, drop to table, lift and start cutting and is lowered or lifted as it should. However, I notice that almost every other cut it would take off to the cut by dragging. I think I was getting away with cutting small things because it was so thin. Just my guess, wish I knew more now on these tables.

Today, I was hoping to cut a 1/4 HR sheet and cut out a welding table found here on the site. This is when things got magnified and I basically have screwed up a 4x4 sheet. I think I can still save it but 4 holes are a loss.

My thought is remove Sheetcam again and reload it. Does this sound like a good option?

I love this site and all the support, Thank you to all the educated helpful members.

-

robertspark

- 4.5 Star Elite Contributing Member

- Posts: 1814

- Joined: Mon Jun 12, 2017 6:43 pm

Re: Sheetcam and THC

I cannot see how the problem is sheetcam...

As you have a self contained THC using the proma SD other than the touchoff all other z motion is controlled by the THC.... Sheetcam ONLY controls the X and Y motion.

You have no ability to control the THC other than setting it correctly internally..... You cannot even enable or disable it from sheetcam or whatever CNC software you are using.

Take some photos of the z axis.... Does it have a floating head and or an ohmic touchoff?

Maybe record a short video of what is happening....

Upload your sheetcam post processor...

Someone may be able to help....

At the moment it's like walking into a garage and saying my car pulls to the right when I brake.... Any ideas? My mate said it's the brakes.....

Like your mechanic.... We need as much info as you can give

As you have a self contained THC using the proma SD other than the touchoff all other z motion is controlled by the THC.... Sheetcam ONLY controls the X and Y motion.

You have no ability to control the THC other than setting it correctly internally..... You cannot even enable or disable it from sheetcam or whatever CNC software you are using.

Take some photos of the z axis.... Does it have a floating head and or an ohmic touchoff?

Maybe record a short video of what is happening....

Upload your sheetcam post processor...

Someone may be able to help....

At the moment it's like walking into a garage and saying my car pulls to the right when I brake.... Any ideas? My mate said it's the brakes.....

Like your mechanic.... We need as much info as you can give

-

mkingaz

- 2 Star Member

- Posts: 58

- Joined: Wed Jun 05, 2019 7:32 pm

- Location: Glendale Arizona

Re: Sheetcam and THC

much appreciated sir, I'll take a video and its very clear on what its doing. Thanks for the great advice.

-

mkingaz

- 2 Star Member

- Posts: 58

- Joined: Wed Jun 05, 2019 7:32 pm

- Location: Glendale Arizona

Re: Sheetcam and THC

when I say clear, you will see it. Thanks again,

-

robertspark

- 4.5 Star Elite Contributing Member

- Posts: 1814

- Joined: Mon Jun 12, 2017 6:43 pm

Re: Sheetcam and THC

I gave you all the info on the Proma SD in your other post here:

viewtopic.php?f=58&t=29380

note: I seem to be getting a very slow connection to their website at the moment (trying to look at the settings for the SD)

what voltage and other settings do you have set within the Proma SD?

viewtopic.php?f=58&t=29380

note: I seem to be getting a very slow connection to their website at the moment (trying to look at the settings for the SD)

what voltage and other settings do you have set within the Proma SD?

-

robertspark

- 4.5 Star Elite Contributing Member

- Posts: 1814

- Joined: Mon Jun 12, 2017 6:43 pm

Re: Sheetcam and THC

Your ARKOK delay probably wants to be set at more than 0.5sec... (the default setting).

I'd also set the High Voltage Setting lower than the default 200V..... probably down to about 160V, as it will allow some gap jump / anti-dive.

Look I don't like the proma..... so its probably best that someone provides some setting for you that work with the Proma SD (I had the standard Proma and sold it long ago...... best thing I ever did)

I'd also set the High Voltage Setting lower than the default 200V..... probably down to about 160V, as it will allow some gap jump / anti-dive.

Look I don't like the proma..... so its probably best that someone provides some setting for you that work with the Proma SD (I had the standard Proma and sold it long ago...... best thing I ever did)

- Attachments

-

- 2019-12-14 19_17_55-Window.png (172.98 KiB) Viewed 1792 times

-

mkingaz

- 2 Star Member

- Posts: 58

- Joined: Wed Jun 05, 2019 7:32 pm

- Location: Glendale Arizona

Re: Sheetcam and THC

Robert thank you so much for the help. Boy this is difficult to learn without having any local contacts, someone I can call or have stop by for a beer and learn a thing or two. Guess I'm going the hard road, I really need a better customer service help side and should have considered this much more before my purchase. I tried the video but having issue's with it being too big.

I went to zero and tried cutting with the torch off and besides the torch going entirely too high during dry cut, it seems to be working right. However, when I went live the torch wants to NOT lift off the table. I zero all out before start. It almost looks like it is .75 below zero. So frustration, I'm going to do some more reading and try to learn some more.

I also thought if I turned off THC and set the torch at .60 above the steel and ran a job, I thought it would run run without moving up and down at all but it does not.

Thanks for the help. I'm going to bet to reading as much as I can.

I went to zero and tried cutting with the torch off and besides the torch going entirely too high during dry cut, it seems to be working right. However, when I went live the torch wants to NOT lift off the table. I zero all out before start. It almost looks like it is .75 below zero. So frustration, I'm going to do some more reading and try to learn some more.

I also thought if I turned off THC and set the torch at .60 above the steel and ran a job, I thought it would run run without moving up and down at all but it does not.

Thanks for the help. I'm going to bet to reading as much as I can.

-

robertspark

- 4.5 Star Elite Contributing Member

- Posts: 1814

- Joined: Mon Jun 12, 2017 6:43 pm

Re: Sheetcam and THC

You cannot turn the THC OFF with the Proma SD..... it detects the voltage, and based upon the H_V setting within it, it decides that the ARKOK is acceptable and starts to control the THC relative to the setpoint voltage up and down.

I'm going to be perfectly blunt.... consider another THC! (I will try to help you, but you have Zero edit: Easy Control over the Proma SD)

easy = via the Mach3 screenset / via the post processor / code snippets / gcode etc

The THC that is "recommended" (used by a LOT of people {not me though.... I went another way}) is the PriceCNC AVHC10 https://www.pricecnc.com/product-page/avhc10 made in Ireland, available via fleebay etc

__________________________________________________________

Can you post the first 30 or so lines of your cnc gcode file (*.nc / *.tap), don't need the whole thing (unless if you are not fussed by posting it in case someone else uses it), just like to have a look at the starting and touchoff sequence. (you can PM me if you want)

There are other guys in Az who have plasma cutters (I've seen them post, but don't know / cant remember their names).

Last edited by robertspark on Sat Dec 14, 2019 3:58 pm, edited 2 times in total.

-

robertspark

- 4.5 Star Elite Contributing Member

- Posts: 1814

- Joined: Mon Jun 12, 2017 6:43 pm

Re: Sheetcam and THC

If you want to disable the Proma (for testing + setup)

go into the settings and set the H-V as 50 volts..... this way regardless of the input voltage the proma will not move the Z-Axis

I would suggest doing this in order to get the THC setup correctly because you need to get the right cutheight (voltage) set

go into the settings and set the H-V as 50 volts..... this way regardless of the input voltage the proma will not move the Z-Axis

I would suggest doing this in order to get the THC setup correctly because you need to get the right cutheight (voltage) set

-

mkingaz

- 2 Star Member

- Posts: 58

- Joined: Wed Jun 05, 2019 7:32 pm

- Location: Glendale Arizona

Re: Sheetcam and THC

Hi Robert,

Thanks again for the help, I'm going to try to turn it off as you mentioned and try to get it set at correct cut height. I was looking at the THC you are recommending. It looks like that one works much like the Promo (does not communicate with software), but are you recommending it becuase it simply works better and/or is easier to control? Thanks again for the help.

Thanks again for the help, I'm going to try to turn it off as you mentioned and try to get it set at correct cut height. I was looking at the THC you are recommending. It looks like that one works much like the Promo (does not communicate with software), but are you recommending it becuase it simply works better and/or is easier to control? Thanks again for the help.

-

robertspark

- 4.5 Star Elite Contributing Member

- Posts: 1814

- Joined: Mon Jun 12, 2017 6:43 pm

Re: Sheetcam and THC

I've written a long (and presently unfinished) detailed reply on my laptop for you to setup the testing procedure.

You may be able to get the proma SD to work for you by using the testing procedure.... The problem is you may have to do a similar thing for every material thichness and type you use so you get your own table of proma SD settings that work for you.

Ill post it in a few hours it maybe worth something to you and give you a bit of understanding under the bonnet

You may be able to get the proma SD to work for you by using the testing procedure.... The problem is you may have to do a similar thing for every material thichness and type you use so you get your own table of proma SD settings that work for you.

Ill post it in a few hours it maybe worth something to you and give you a bit of understanding under the bonnet

-

robertspark

- 4.5 Star Elite Contributing Member

- Posts: 1814

- Joined: Mon Jun 12, 2017 6:43 pm

Re: Sheetcam and THC

If you don't want to get rid of the Proma SD and want to try your best to get it to work for you, I'd suggest the following....

Ok you have a hypertherm 45XP, so your cut height will always be with standard consumables - 0.06" with a pierce height of 0.15" (fine cut consumables can change.... just check the book STD settings)

https://www.hypertherm.com/Download?fil ... &zip=False

Now I would get myself a simple test program..... say cut a 4" x 2" rectangle out.... that way you have a bit of a straight run on both sides and you should be able to get a small piece of metal relatively level over 4" of cut length travel (because you are going to be turning the THC OFF).

What you want to do is observe the voltage reading on the proma SD (the numbers)

What you want to do is get the machine to do a touch off to zero the tip of the torch (allow for any switch offset [presume you have a floating head])

Then you want it to raise to the pierce height (0.15" above the material)

OK now you have a problem...... does your motion controller make use of the ARCOK signal from within the PMX45XP or does the proma guess it???? (you will need to check the wiring from the PMX45XP..... how is it wired up to the controller..... does it use the CPC (Circular plastic connector) or does it use a RAW Torch Voltage Feed???)

If your machine has the ArcOK Signal wired to the controller, then great you don't have to guess the transfer signal..... otherwise you will need to allow a bit of extra time to the pierce time to guarantee that the Arc Transfer has taken place BEFORE starting the Pierce Delay....

If the time you guess is too great then all that will happen is you will get a bigger pierce hole than you need.... given the torch will remove more material than it needs to..... if you guess too short... then the torch may not pierce all the way through the material before your machine starts to move the torch.

Another Caveat: ...... some users report that the first pierce is not consistent with subsequent pierces (this tends to be with dimpling / center punch marking)..... suggestion..... run a pierce and short cut somewhere on a bit of scrap... then start your testing shortly after this there (may) be an instance that the first pierce cleans out the torch tip and also metals expand and get into their operating temperature after the first pierce (i.e. they are now 100% cold and shrunk) hence you may get more consistent testing if you ignore the first pierce and short cut .... then perform you testing.

If you don't know what your switch offset is for your floating head, what I suggest is doing something like this...

(this presumes that your floating head is wired to your PROBE INPUT PORT)..... sometimes people can use G28.1 to do the offset, this uses a Home input switch.... not the Probe Input

place a piece of thin paper on the top of the material, between the torch and the top of the material.... allow for an inch or a couple of inches clearance between the paper and the torch tip

Run via the MDI a "G31 Z-4 F15" (probing routine, for the Z axis, probing downwards at a Feedrate of 15"/min)

When the torch touches the material (+paper) it should stop moving downwards (if not you may need to press the E-stop!, given it's not wired to the probing input).

Now you set a temporary offset to zero the Z axis "G92 Z0"

Now you slowly jog upwards away from the material, 1 button press at a time using the "Pg Up" button

Try to slide the paper out from under the torch after each button press

When the paper slides out you now know the switch offset! say it's 0.02"

All you do when you do the G92 above is as follows "G92 Z-0.02" that way the torch is offset negative 0.02" below zero, so when you do the next move (to the pierce height) it will be "G00 Z0.15" the switch offset will be taken care of

say you intend to cut 1/4" mild steel with standard consumables .... the "book" recommends a pierce delay of 0.6 seconds and a feedrate of 48 " / min

your test gcode could be something like this: (note I don't know if you are using G31 or G28.1 to do your probing sequence)

G90 (absolute distance mode)

G92 X0 Y0 (zero the machines current X Y co-ordinates)

G31 Z-4 F15 (touchoff workpiece)

G92 Z-0.02 (switch offset + zero Z axis)

G0 Z0.15 (retract to pierce height)

M3 (fire the torch)

(if you have ARCOK being fed into the motion controller from the 45XP)

G4 P0.6 (if you machine is set for delay in seconds.... or else it will be G4 P600 for a machine set with a delay in miliseconds)

(if your machine has no Arc OK.... then try this)

G4 P1 (for a machine with a delay set in seconds or else G4 P1000 for a machine set with a delay in miliseconds).

G0 Z0.06 (drop to cut height)

G1 X4 F48 (feedrate X move 4" at a feedrate of 48"/min)

G1 Y2

G1 X0

G1 Y0

M5 (torch off)

G0 Z1 (torch retract 1" above workpiece)

whilst the above motion is cutting what you want to do is observe the numbers on the Proma SD..... the voltage should take a (short) while to stabalise and also the voltage will change (rise) at the corners ( what you are trying to do is find out what the voltage setpoint needs to be for the proma at the prescribed cut height of 0.06" above the workpiece.

Once the cut is done and you have the piece in your hand you need to inspect its edge for quality of the cut and angularity

(I would have posted the link.... but the Hypertherm website is down for maintenance.... I think it is this one.... there are a few more ones about, just search google for Hypertherm cut quality as they do some good guidance as to what you are looking for and what may be wrong)

https://www.hypertherm.com/learn/articl ... t-quality/

Ok you have a hypertherm 45XP, so your cut height will always be with standard consumables - 0.06" with a pierce height of 0.15" (fine cut consumables can change.... just check the book STD settings)

https://www.hypertherm.com/Download?fil ... &zip=False

Now I would get myself a simple test program..... say cut a 4" x 2" rectangle out.... that way you have a bit of a straight run on both sides and you should be able to get a small piece of metal relatively level over 4" of cut length travel (because you are going to be turning the THC OFF).

What you want to do is observe the voltage reading on the proma SD (the numbers)

What you want to do is get the machine to do a touch off to zero the tip of the torch (allow for any switch offset [presume you have a floating head])

Then you want it to raise to the pierce height (0.15" above the material)

OK now you have a problem...... does your motion controller make use of the ARCOK signal from within the PMX45XP or does the proma guess it???? (you will need to check the wiring from the PMX45XP..... how is it wired up to the controller..... does it use the CPC (Circular plastic connector) or does it use a RAW Torch Voltage Feed???)

If your machine has the ArcOK Signal wired to the controller, then great you don't have to guess the transfer signal..... otherwise you will need to allow a bit of extra time to the pierce time to guarantee that the Arc Transfer has taken place BEFORE starting the Pierce Delay....

If the time you guess is too great then all that will happen is you will get a bigger pierce hole than you need.... given the torch will remove more material than it needs to..... if you guess too short... then the torch may not pierce all the way through the material before your machine starts to move the torch.

Another Caveat: ...... some users report that the first pierce is not consistent with subsequent pierces (this tends to be with dimpling / center punch marking)..... suggestion..... run a pierce and short cut somewhere on a bit of scrap... then start your testing shortly after this there (may) be an instance that the first pierce cleans out the torch tip and also metals expand and get into their operating temperature after the first pierce (i.e. they are now 100% cold and shrunk) hence you may get more consistent testing if you ignore the first pierce and short cut .... then perform you testing.

If you don't know what your switch offset is for your floating head, what I suggest is doing something like this...

(this presumes that your floating head is wired to your PROBE INPUT PORT)..... sometimes people can use G28.1 to do the offset, this uses a Home input switch.... not the Probe Input

place a piece of thin paper on the top of the material, between the torch and the top of the material.... allow for an inch or a couple of inches clearance between the paper and the torch tip

Run via the MDI a "G31 Z-4 F15" (probing routine, for the Z axis, probing downwards at a Feedrate of 15"/min)

When the torch touches the material (+paper) it should stop moving downwards (if not you may need to press the E-stop!, given it's not wired to the probing input).

Now you set a temporary offset to zero the Z axis "G92 Z0"

Now you slowly jog upwards away from the material, 1 button press at a time using the "Pg Up" button

Try to slide the paper out from under the torch after each button press

When the paper slides out you now know the switch offset! say it's 0.02"

All you do when you do the G92 above is as follows "G92 Z-0.02" that way the torch is offset negative 0.02" below zero, so when you do the next move (to the pierce height) it will be "G00 Z0.15" the switch offset will be taken care of

say you intend to cut 1/4" mild steel with standard consumables .... the "book" recommends a pierce delay of 0.6 seconds and a feedrate of 48 " / min

your test gcode could be something like this: (note I don't know if you are using G31 or G28.1 to do your probing sequence)

G90 (absolute distance mode)

G92 X0 Y0 (zero the machines current X Y co-ordinates)

G31 Z-4 F15 (touchoff workpiece)

G92 Z-0.02 (switch offset + zero Z axis)

G0 Z0.15 (retract to pierce height)

M3 (fire the torch)

(if you have ARCOK being fed into the motion controller from the 45XP)

G4 P0.6 (if you machine is set for delay in seconds.... or else it will be G4 P600 for a machine set with a delay in miliseconds)

(if your machine has no Arc OK.... then try this)

G4 P1 (for a machine with a delay set in seconds or else G4 P1000 for a machine set with a delay in miliseconds).

G0 Z0.06 (drop to cut height)

G1 X4 F48 (feedrate X move 4" at a feedrate of 48"/min)

G1 Y2

G1 X0

G1 Y0

M5 (torch off)

G0 Z1 (torch retract 1" above workpiece)

whilst the above motion is cutting what you want to do is observe the numbers on the Proma SD..... the voltage should take a (short) while to stabalise and also the voltage will change (rise) at the corners ( what you are trying to do is find out what the voltage setpoint needs to be for the proma at the prescribed cut height of 0.06" above the workpiece.

Once the cut is done and you have the piece in your hand you need to inspect its edge for quality of the cut and angularity

(I would have posted the link.... but the Hypertherm website is down for maintenance.... I think it is this one.... there are a few more ones about, just search google for Hypertherm cut quality as they do some good guidance as to what you are looking for and what may be wrong)

https://www.hypertherm.com/learn/articl ... t-quality/

-

robertspark

- 4.5 Star Elite Contributing Member

- Posts: 1814

- Joined: Mon Jun 12, 2017 6:43 pm

Re: Sheetcam and THC

The hypertherm book gives you a load of voltage settings, the problem with the Proma (and all THC's) is the numbers may not match the book (exactly).... hence what you are trying to do is find what voltage the proma is reading (it should be close to the book number) when you are cutting at the book defined cut height or very close to it. You can then use this as your setpoint for the proma.

Say the book says (1/4" Mild Steel, Air Shielded [std consumables]) 130V.... but the proma is reading say 135V..... what this means is if you set the proma at 130V, the proma will be trying to lower the voltage to 130V and it will dive into the workpiece ... hence it may alter the cut height incorrectly.... this may be because the Proma is not reading the voltage accurately or whatever (the voltage [number] is not important ..... just as long as the number is consistent ..... this 5V difference gives you an indication that maybe you need to adjust all the book values by 5V or maybe that the voltage is scaled a bit (5V at 130V.... may be 4.6V at 120V (5/130x120)....

You have to remember that if the cut height is 0.06" and the 1plasma torch volt is about 0.0052".... for a 0.06" height there is only about ~11 volts between your torch flying above the material and crashing into / dragging across the material... a 5V sampling error is 1/2 the cut height..... plus the Proma SD does not allow you to program the hysterysis (the Proma 150 had a minimum hysteresis [dead band] of +/- 1 VOLT (i.e. 1 volt above or 1 volt below the setpoint and the torch would not move.... hence with a 5V sampling error / difference from the book..... it would actually be a minimum of 6V {5V+1} before the torch corrected... so the torch could be even closer to the material than the book cut height.

some torch sampling voltage info here (plus this whole document is a good read with a beer to hand)

http://linuxcnc.org/docs/devel/html/pla ... cnc_plasma

Say the book says (1/4" Mild Steel, Air Shielded [std consumables]) 130V.... but the proma is reading say 135V..... what this means is if you set the proma at 130V, the proma will be trying to lower the voltage to 130V and it will dive into the workpiece ... hence it may alter the cut height incorrectly.... this may be because the Proma is not reading the voltage accurately or whatever (the voltage [number] is not important ..... just as long as the number is consistent ..... this 5V difference gives you an indication that maybe you need to adjust all the book values by 5V or maybe that the voltage is scaled a bit (5V at 130V.... may be 4.6V at 120V (5/130x120)....

You have to remember that if the cut height is 0.06" and the 1plasma torch volt is about 0.0052".... for a 0.06" height there is only about ~11 volts between your torch flying above the material and crashing into / dragging across the material... a 5V sampling error is 1/2 the cut height..... plus the Proma SD does not allow you to program the hysterysis (the Proma 150 had a minimum hysteresis [dead band] of +/- 1 VOLT (i.e. 1 volt above or 1 volt below the setpoint and the torch would not move.... hence with a 5V sampling error / difference from the book..... it would actually be a minimum of 6V {5V+1} before the torch corrected... so the torch could be even closer to the material than the book cut height.

some torch sampling voltage info here (plus this whole document is a good read with a beer to hand)

http://linuxcnc.org/docs/devel/html/pla ... cnc_plasma

-

robertspark

- 4.5 Star Elite Contributing Member

- Posts: 1814

- Joined: Mon Jun 12, 2017 6:43 pm

Re: Sheetcam and THC

If you can get the proma SD to control the voltage on straight cuts you could add a simple circuit with a reed relay which would allow you to inhibit THC at the corners, small arc radii and also the end of the cut using gcode

..... Basically adding one of the missing features of a THC..... The ability to inhibit THC during the cut if the gcode settings required it

..... Basically adding one of the missing features of a THC..... The ability to inhibit THC during the cut if the gcode settings required it

-

mkingaz

- 2 Star Member

- Posts: 58

- Joined: Wed Jun 05, 2019 7:32 pm

- Location: Glendale Arizona

Re: Sheetcam and THC

Hi Robert,

Again, thanks for taking all the time to help me out. I simply love this site. After readying your post I'm starting to learn more and more. Some of this is still over my head but I'm pretty sure I'm getting most of it and can work on a few test cuts. I was reading up on the THC controller you recommended and it looks like it does communicate with Sheet cam is that correct?

Another thing I observed was in your most recent follow up reply you talked about the SD Promo and volts and they should be somewhat close to the Hypertherm settings. This was interesting, I'm no where even close to them. I typically cut 18 -10 ga at about 80-90 volts on the SD Promo, and I'm running at 30-40 amps with speeds in the 100-130 range. I get some dross depends how large or small the project but it cleans of easy. I'm still not sure how to tell if I'm getting slow speed or high speed dross. When I put the 1/4 plate on I decided to increase the volts but was still only at 105 volts and that's when my head would crash into the steel and basically slide from hole to hole. It simply simply would not get off the steel.

After my day job I'm headed to the steep yard for some scrape stuff and will try your test cuts and I think this will help with several things. Get me a better understanding of how to adjust and play with the table all while learning how it works with a bit more depth. I'll follow your advice and see what happens.

Thanks again my friend, much appreciated.

Again, thanks for taking all the time to help me out. I simply love this site. After readying your post I'm starting to learn more and more. Some of this is still over my head but I'm pretty sure I'm getting most of it and can work on a few test cuts. I was reading up on the THC controller you recommended and it looks like it does communicate with Sheet cam is that correct?

Another thing I observed was in your most recent follow up reply you talked about the SD Promo and volts and they should be somewhat close to the Hypertherm settings. This was interesting, I'm no where even close to them. I typically cut 18 -10 ga at about 80-90 volts on the SD Promo, and I'm running at 30-40 amps with speeds in the 100-130 range. I get some dross depends how large or small the project but it cleans of easy. I'm still not sure how to tell if I'm getting slow speed or high speed dross. When I put the 1/4 plate on I decided to increase the volts but was still only at 105 volts and that's when my head would crash into the steel and basically slide from hole to hole. It simply simply would not get off the steel.

After my day job I'm headed to the steep yard for some scrape stuff and will try your test cuts and I think this will help with several things. Get me a better understanding of how to adjust and play with the table all while learning how it works with a bit more depth. I'll follow your advice and see what happens.

Thanks again my friend, much appreciated.

-

mkingaz

- 2 Star Member

- Posts: 58

- Joined: Wed Jun 05, 2019 7:32 pm

- Location: Glendale Arizona

Re: Sheetcam and THC

Talking more about Volts, interesting because I was just reading a post by Jim Colt that talked about lower cut speeds. If y ou cut slower than manufacturers specs. The THC will move the torch closer to the plate too slow and it will crash in to the plate (this is what was happening for me). If you want to cut slower than the manufacturers specs increase the arc voltage until the torch is a the best cut. I think I was at 110 volts trying to get as close to the book as possible but I was diving into the metal. I have several test to get done tonight.

-

robertspark

- 4.5 Star Elite Contributing Member

- Posts: 1814

- Joined: Mon Jun 12, 2017 6:43 pm

Re: Sheetcam and THC

edit: oops may have got that wrong... (read the guide....) VVVV

here is a guide for you

https://www.hypertherm.com/Download?fil ... &zip=False

here is a guide for you

https://www.hypertherm.com/Download?fil ... &zip=False

-

Old Iron

- 3.5 Star Member

- Posts: 681

- Joined: Wed Nov 26, 2014 5:12 pm

Re: Sheetcam and THC

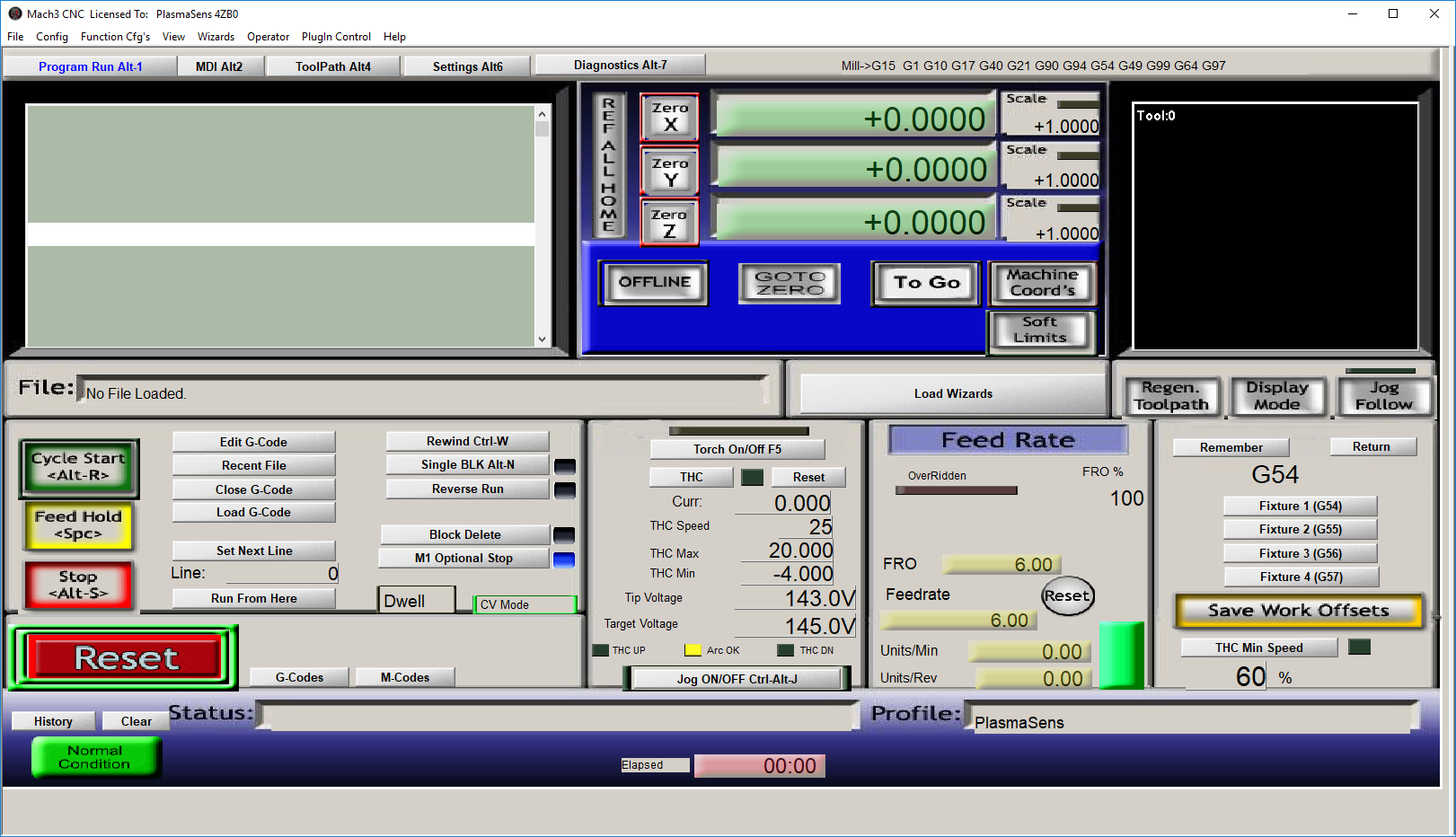

Are you using Mach3?

The pic below is what my Mach3 screen looks like. In the middle of the screen you can see it has a toggle button to turn the THC on and off.

I have the Proma 150

Create a straight line test cut.

Turn off the THC with the toggle, hit the Cycle Start button. Let the torch run several inches look at the volts on the Proma to see what it is displaying then, set the volts to that reading using the up or down arrows on the Proma.

You can then fine tune the Proma voltage to get the torch to run at .060 above the material by adjusting the volts up or down.

After making the adjustment, click the Stop button in mid cut and use the feeler gauge to see if the torch is running a the .060 cut height.

The pic below is what my Mach3 screen looks like. In the middle of the screen you can see it has a toggle button to turn the THC on and off.

I have the Proma 150

Create a straight line test cut.

Turn off the THC with the toggle, hit the Cycle Start button. Let the torch run several inches look at the volts on the Proma to see what it is displaying then, set the volts to that reading using the up or down arrows on the Proma.

You can then fine tune the Proma voltage to get the torch to run at .060 above the material by adjusting the volts up or down.

After making the adjustment, click the Stop button in mid cut and use the feeler gauge to see if the torch is running a the .060 cut height.

-

robertspark

- 4.5 Star Elite Contributing Member

- Posts: 1814

- Joined: Mon Jun 12, 2017 6:43 pm

Re: Sheetcam and THC

He has the proma SD

Not the standard proma 150

There does not appear to be a controllable input for the proma SD

Not the standard proma 150

There does not appear to be a controllable input for the proma SD

-

mkingaz

- 2 Star Member

- Posts: 58

- Joined: Wed Jun 05, 2019 7:32 pm

- Location: Glendale Arizona

Re: Sheetcam and THC

That is correct, my Mach 3 looks the same without the tip volts.

I finally picked up some scrap 1/4 this morning to test on. I'm hoping this is a simply question. If I'm running 16 guage with NO issues, moving to 1/4 should run the same with a simply tool change in Sheetcam correct? Tool is set for the 1/4, speed, etc. Looking at the Hypertherm book the volts don't really change that much at all. I'm feeling like I have a setting wrong. I'm gong to play with the table on scrap this afternoon.

I finally picked up some scrap 1/4 this morning to test on. I'm hoping this is a simply question. If I'm running 16 guage with NO issues, moving to 1/4 should run the same with a simply tool change in Sheetcam correct? Tool is set for the 1/4, speed, etc. Looking at the Hypertherm book the volts don't really change that much at all. I'm feeling like I have a setting wrong. I'm gong to play with the table on scrap this afternoon.

-

robertspark

- 4.5 Star Elite Contributing Member

- Posts: 1814

- Joined: Mon Jun 12, 2017 6:43 pm

Re: Sheetcam and THC

Yes the tool change should provide you with the revised feedrate and kerf width offset

- djreiswig

- 4.5 Star Elite Contributing Member

- Posts: 1934

- Joined: Thu Nov 19, 2015 10:02 pm

- Location: SE Nebraska

Re: Sheetcam and THC

Don't forget to change the lead in length. It's not part of the tool settings. I usually set it the same as the thickness.

2014 Bulltear (StarLab) 4x8

C&CNC EtherCut

Mach3, SheetCam, Draftsight

Hypertherm PM65

Oxy/Acetylene Flame Torch

Pneumatic Plate Marker, Ohmic, 10 inch Rotary Chuck (in progress)

C&CNC EtherCut

Mach3, SheetCam, Draftsight

Hypertherm PM65

Oxy/Acetylene Flame Torch

Pneumatic Plate Marker, Ohmic, 10 inch Rotary Chuck (in progress)

-

mkingaz

- 2 Star Member

- Posts: 58

- Joined: Wed Jun 05, 2019 7:32 pm

- Location: Glendale Arizona

Re: Sheetcam and THC

excellent to know, will do. I'm heading home soon to run test cuts. Last question for today, but thanks.

Is it better to run text lines, or I'm really trying to cut a welding table and they are small circles. I also thought about 6 different size circles?

Is it better to run text lines, or I'm really trying to cut a welding table and they are small circles. I also thought about 6 different size circles?

-

robertspark

- 4.5 Star Elite Contributing Member

- Posts: 1814

- Joined: Mon Jun 12, 2017 6:43 pm

Re: Sheetcam and THC

Circles are a difficult one.... because the recommendation is that circles under 1 1/4" dia are cut at ~60% of the linear feedrate (there is some math behind this that I worked out)..... and also the THC should be disabled....

Here is a quote from one of Jim Colts posts (I was trying to find a write-up he did a while ago):

bigger / longer writeup and discussion here:

viewtopic.php?t=17107#p99505

And finally.... check your cut direction is correct!!! (it will give you a (greater) bevel if cutting the wrong direction)

Clockwise around a part (outside cut) and anticlockwise for a hole...

https://www.hypertherm.com/Download?fil ... &zip=False

Here is a quote from one of Jim Colts posts (I was trying to find a write-up he did a while ago):

https://www.cnczone.com/forums/general- ... post5355794. Part programming. For holes.....plasma likes a straight lead in....with adequate length to allow the height control to achieve proper cut height before the cut path is reached....then do not use a lead out (that works well with oxy fuel)...rather use an overburn (overburn is when you extend the radius of the hole past 360 degrees).....and if the controller or part program has the capability...shut the plasma off while in the overburn area...and keep the motion going for at least 20 degrees or so past 360 degrees. (this allows the plasma to extinguish while the torch is still moving....which smooths out the end of the cut. Holes should also be cut at a slower speed as compared to the outside contour of the cut....60% of the cut speed is a good starting point.

bigger / longer writeup and discussion here:

viewtopic.php?t=17107#p99505

And finally.... check your cut direction is correct!!! (it will give you a (greater) bevel if cutting the wrong direction)

Clockwise around a part (outside cut) and anticlockwise for a hole...

https://www.hypertherm.com/Download?fil ... &zip=False

-

mkingaz

- 2 Star Member

- Posts: 58

- Joined: Wed Jun 05, 2019 7:32 pm

- Location: Glendale Arizona

Re: Sheetcam and THC

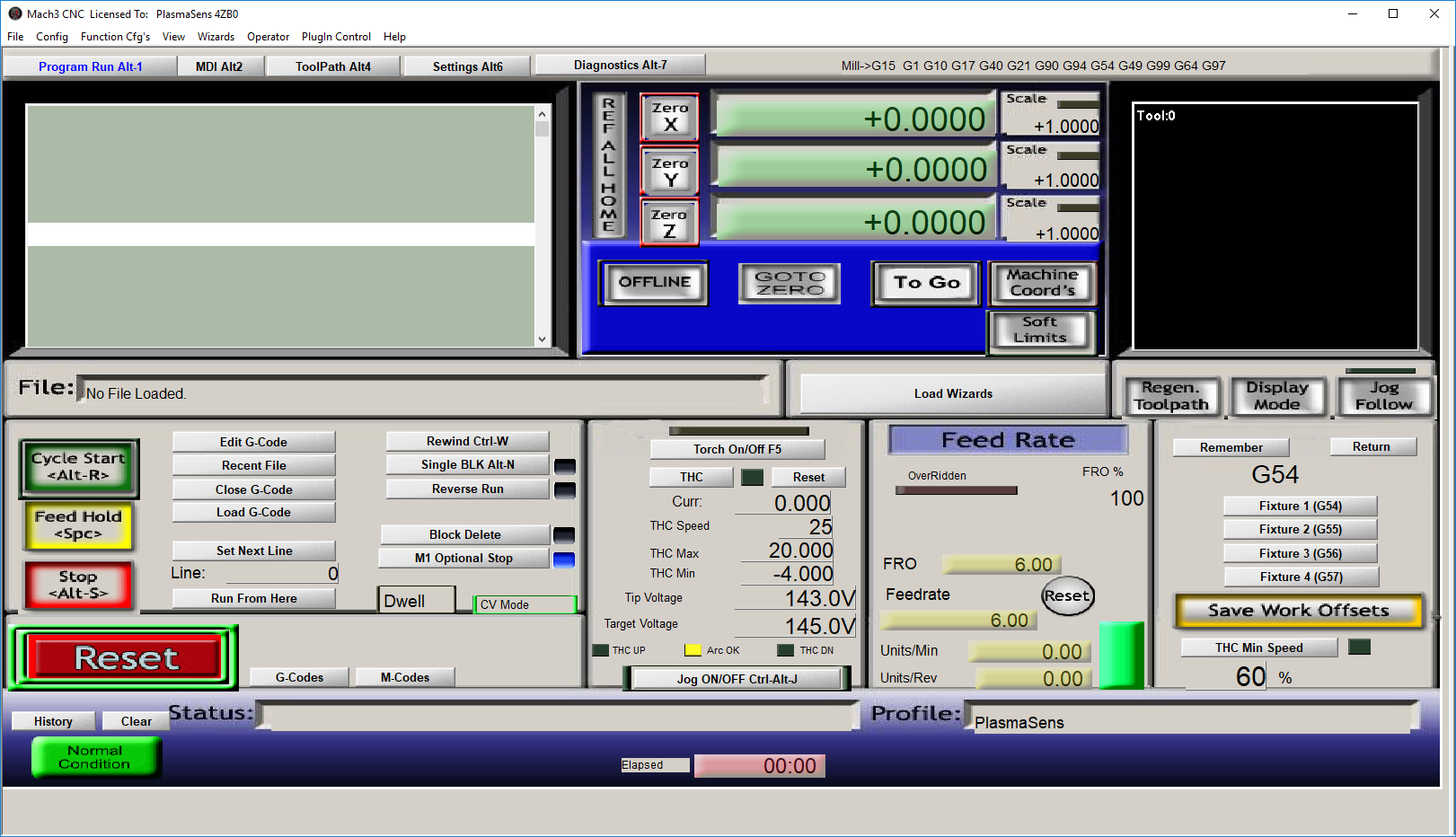

Ok, I reset and calibrated the THC and the switchoff set. Seems to be cutting much better but I still have a few issues.

I turned the volts to 90, 45 amps and went with book settings. Seemed to work pretty good, I think I could slow down a little. However, since I purchased this table it seems like the THC will not set the right height every other cut.

cuts in order:

1 - straight line at 92 volts, heavy dross so I lowered to 90.

2- outside to in circles, they look really nice and have very little dross. I was happy with this.

3 - two circle first on closest to you looked ok, second one looks horrible and xp 45 miss fired on last two holes.

4 - again first cut (hole 3) does not look the greatest, second hole height seems to be off hole looks like sh@t, third torch dragged and move part

and forth hole seemed like torch was low and not round.

what would make the torch not set the right height after every cut.

Thanks again for the help guys, feels like I take one step forward and another backwards but learning.

I turned the volts to 90, 45 amps and went with book settings. Seemed to work pretty good, I think I could slow down a little. However, since I purchased this table it seems like the THC will not set the right height every other cut.

cuts in order:

1 - straight line at 92 volts, heavy dross so I lowered to 90.

2- outside to in circles, they look really nice and have very little dross. I was happy with this.

3 - two circle first on closest to you looked ok, second one looks horrible and xp 45 miss fired on last two holes.

4 - again first cut (hole 3) does not look the greatest, second hole height seems to be off hole looks like sh@t, third torch dragged and move part

and forth hole seemed like torch was low and not round.

what would make the torch not set the right height after every cut.

Thanks again for the help guys, feels like I take one step forward and another backwards but learning.

- Attachments

-

- IMG_6225.jpg (44.31 KiB) Viewed 1729 times

-

- IMG_6224.jpg (68.68 KiB) Viewed 1729 times

-

- IMG_6223.jpg (76.57 KiB) Viewed 1729 times

-

- IMG_6222.jpg (77.27 KiB) Viewed 1729 times

-

- IMG_6221.jpg (51.76 KiB) Viewed 1729 times

-

- IMG_6220.jpg (58.1 KiB) Viewed 1729 times