Thought that I would share.

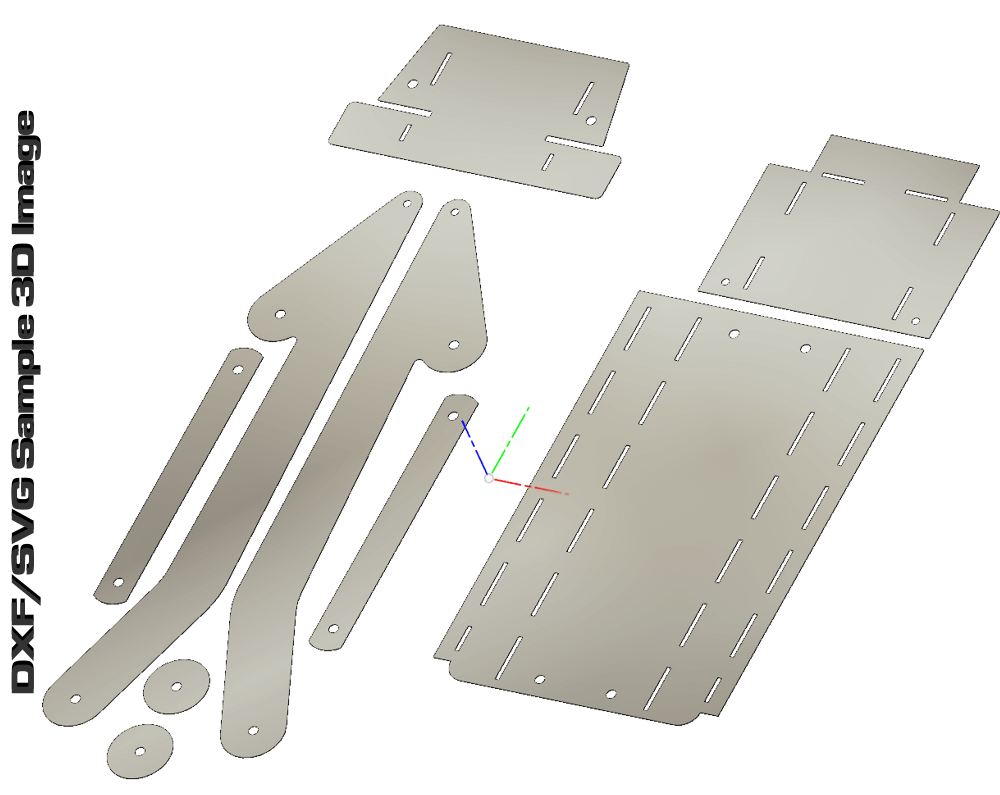

I used 16 gauge and 12-gauge cold roll and used 3/16" steel pop rivets at the (6) pivot points.

Also, the washer (12 gauge) is to shim the handle out so that it doesn't crash.

I was planning on using a wood handle, so I added holes to attach screws into the round handle.

I later found some 3/4" tube out in the bone yard and decided to just weld it in place of wood.

So, you may want to delete the handle holes if you want a steel handle.

I needed to grease the slide a bit to get it to glide very smoothly.

Also, the small 16-gauge bed welds to the 16-gauge vertical channel to form a table and bed for the can to lay on which is the only welding needed unless you decide to weld a handle on in place of a wooden handle.

Hope you can use it. Feel free modify and use as you wish.

Edit: Note, the (2) 12-gauge washers will be too big and would need to be shrunk down to 3/4"

They protrude out the back. You could also just slice them off so that they don't stick out.

I forgot to resize them, but it is a super easy fix. Inside hole is a 7/32" for 3/16" rivets.

Download DXF/SVG

Download DXF/SVG