Pretty damned functional considering the cost and size.

I purchased the Gantry from Precision Plasma LLC In Minnesota

and I purchased the Electronics package from CandCNC in Texas.

620 Oz In Motors, Ethercut with DTHC-IV, Also Router and Scanning function.

I built the base of the table and the water pan/slat bed.

Drilled and Tapped the frame for the CRS Rails, Drilled the CRS Rails as well on the mill/drill.

Steel from the local steel supply. A Co-Worker said "It Looks ALMOST Professionally Built"

I said "Thanks... I think...."

Pic

a "Supereyes B005" Camera from Amazon ($28) and the software from Sheetcam (Stable Designs) called "Scanything" WORKS GREAT! This is just a test but will be ultra handy when someone drags in a part they want duplicated or a pile of cardboard templates...

Coke Logo - YouTube

That is the Supereyes Camera on the right of the Z axis. the Silver tube...

Same "Coke" Logo routed into finished plywood, works great.

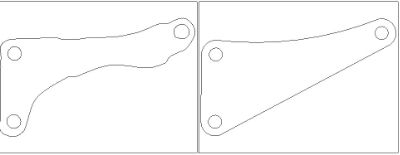

My Brother in law broke the Alternator Bracket on his race car and needed it repaired.

This is the Umpteenth time To "repair it...

So I decided I would just make a NEW part.

Well I scanned it into a .DXF file using my CNC table... and Sheetcam "Scanything"

Then I "Fixed" it in CAD making it I believe SUPERIOR to the original...

Then I engraved the thing with his racing team name. Just using the Font available in Sheetcam

Installed

I use this machine for engraving and routing too. Works Fine but I make the fixtures for the parts

And they are designed so that I can install them on the machine and level them to the machine then when I cut parts I don't get Thick and Thin Spots.

I am currently using the plasma I had on hand, a Hypertherm PM30, modified with the RAV card and Current Probe from CandCNC... seems to work OK, on thicker materials I would be getting close to the duty cycle, but on thinner stuff I am doing just fine so far. a PM65 or 85 is on my Christmas list.