Cleanup & Packaging of Hundreds of Cut Items

-

beefy

- 4.5 Star Member

- Posts: 1504

- Joined: Fri Jan 18, 2013 3:19 am

Cleanup & Packaging of Hundreds of Cut Items

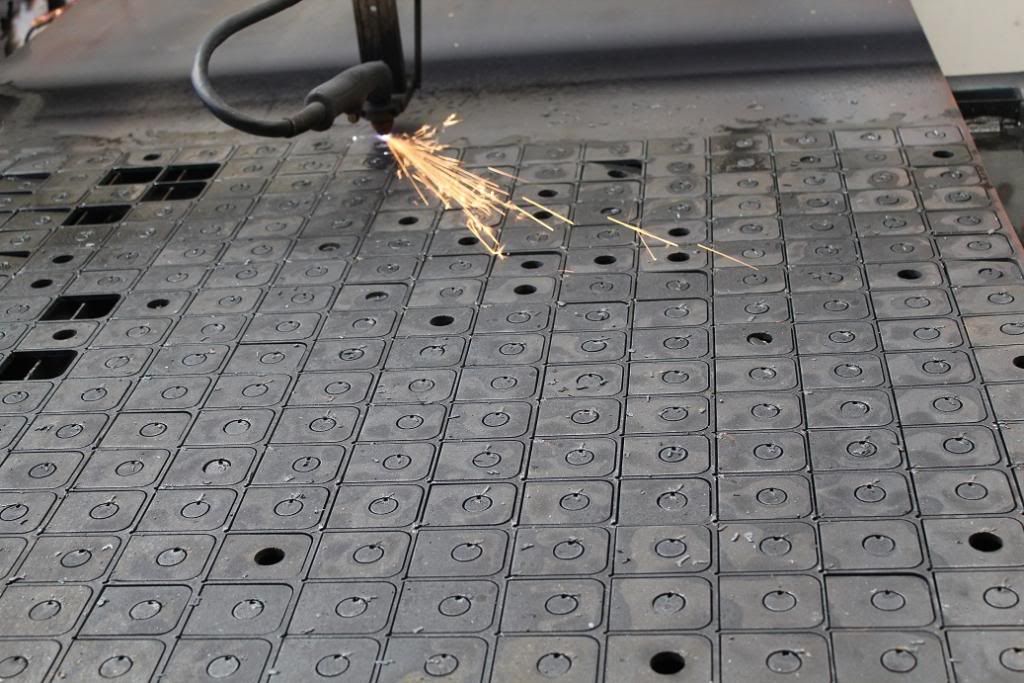

After viewing a thread about service cutting hundreds of nested parts, I had a play with my software to try out different nesting methods, chain cutting possibilities, etc. This nest was a bunch of small circles a bit more than 60mm in diameter and managed to get over 640 parts in the sheet.

Jim Colt did a great write up on how he priced a nested cut for a customer, but he mentioned about the dross cleaning and the packaging too. Should be obvious but that hadn't occured to me. Jim cut his parts with settings that minimised dross but didn't give as good edge quality, which in this case wasn't important. Of course that won't always be the case and edge quality may be more important .

I know there's muriatic acid, and the tumbler barrel methods (as long as that won't bend the parts) for cleaning.

Have any of you guys done a nested cut for a customer where there's 100s of parts. If so how did you clean the dross (not one by one I hope) and how did you package all those parts, I mean they'll be heavy so what boxes or whatever did you use. Just trying to get an idea in my head what's involved and what packaging stuff I'd need if a job like this ever comes along.

And of course a lot of small cut items would drop down between the slats and have to be retrieved too. All of this has to be considered in figuring out a final price for the job.

Keith.

Jim Colt did a great write up on how he priced a nested cut for a customer, but he mentioned about the dross cleaning and the packaging too. Should be obvious but that hadn't occured to me. Jim cut his parts with settings that minimised dross but didn't give as good edge quality, which in this case wasn't important. Of course that won't always be the case and edge quality may be more important .

I know there's muriatic acid, and the tumbler barrel methods (as long as that won't bend the parts) for cleaning.

Have any of you guys done a nested cut for a customer where there's 100s of parts. If so how did you clean the dross (not one by one I hope) and how did you package all those parts, I mean they'll be heavy so what boxes or whatever did you use. Just trying to get an idea in my head what's involved and what packaging stuff I'd need if a job like this ever comes along.

And of course a lot of small cut items would drop down between the slats and have to be retrieved too. All of this has to be considered in figuring out a final price for the job.

Keith.

2500 x 1500 water table

Powermax 1250 & Duramax torch (because of the new $$$$ync system, will buy Thermal Dynamics next)

LinuxCNC

Sheetcam

Alibre Design 3D solid modelling

Coreldraw 2019

Powermax 1250 & Duramax torch (because of the new $$$$ync system, will buy Thermal Dynamics next)

LinuxCNC

Sheetcam

Alibre Design 3D solid modelling

Coreldraw 2019

- AnotherDano

- 4 Star Member

- Posts: 806

- Joined: Fri Dec 18, 2009 11:52 pm

- Location: Laramie, Wyoming

- Contact:

Re: Cleanup & Packaging of Hundreds of Cut Items

My job was to cut 350 small cowboy boots at 3.5" for keychain giveways.

What a PITA!

I finally settled on a template to drop them into, a dozen at a time.

Think of a sheet of cookie dough after the cookies have been cut and removed.

The template was clamped to a FLAT, THICK sheet of plate steel.

The pieces were dropped into the cutouts and a belt sander (50 grit) used to remove what was left of the dross.

That gave me a nice crisp edge. I hate using a flap disk due to the gouging, however slight. There were some places that the flap disk was needed, but the piece being held in place by the template minimized the gouging.

What a PITA!

I finally settled on a template to drop them into, a dozen at a time.

Think of a sheet of cookie dough after the cookies have been cut and removed.

The template was clamped to a FLAT, THICK sheet of plate steel.

The pieces were dropped into the cutouts and a belt sander (50 grit) used to remove what was left of the dross.

That gave me a nice crisp edge. I hate using a flap disk due to the gouging, however slight. There were some places that the flap disk was needed, but the piece being held in place by the template minimized the gouging.

You currently do not have access to download this file.

To gain download access for DXF, SVG & other files Click Here

Dano Roberts

droberts@ironpequod.com

PlasmaCam DHC-2 v3.11

Hypertherm PowerMax-30

Serving Laramie, Wy since Thursday

droberts@ironpequod.com

PlasmaCam DHC-2 v3.11

Hypertherm PowerMax-30

Serving Laramie, Wy since Thursday

-

beefy

- 4.5 Star Member

- Posts: 1504

- Joined: Fri Jan 18, 2013 3:19 am

Re: Cleanup & Packaging of Hundreds of Cut Items

Thanks for the reply Dano.

So I guess what you are saying is you wouldn't do that again unless you had an automated way of removing the dross, like a tumbler or a muriatic acid bath ??

Love to know how long everything took you, did your hourly rate end up very low.

Hey that's just got me thinking. You could almost use the leftover scrap as the holding template (if you've got a big enough work bench and the steel isn't warped all over). I like your template idea, simple but I might not have thought of that.

Keith.

So I guess what you are saying is you wouldn't do that again unless you had an automated way of removing the dross, like a tumbler or a muriatic acid bath ??

Love to know how long everything took you, did your hourly rate end up very low.

Hey that's just got me thinking. You could almost use the leftover scrap as the holding template (if you've got a big enough work bench and the steel isn't warped all over). I like your template idea, simple but I might not have thought of that.

Keith.

2500 x 1500 water table

Powermax 1250 & Duramax torch (because of the new $$$$ync system, will buy Thermal Dynamics next)

LinuxCNC

Sheetcam

Alibre Design 3D solid modelling

Coreldraw 2019

Powermax 1250 & Duramax torch (because of the new $$$$ync system, will buy Thermal Dynamics next)

LinuxCNC

Sheetcam

Alibre Design 3D solid modelling

Coreldraw 2019

- AnotherDano

- 4 Star Member

- Posts: 806

- Joined: Fri Dec 18, 2009 11:52 pm

- Location: Laramie, Wyoming

- Contact:

Re: Cleanup & Packaging of Hundreds of Cut Items

A tumbler would work. I thought of a contractor-sized cement mixer but I like my neighbors. Too noisy.beefy wrote:Thanks for the reply Dano.

So I guess what you are saying is you wouldn't do that again unless you had an automated way of removing the dross, like a tumbler or a muriatic acid bath ??

Love to know how long everything took you, did your hourly rate end up very low.

Keith.

I'm not sold on the muriatic acid either. There is no secure place to put it outside the shop and it might take a couple of days. Again; smell and neighbors. If you use it inside, no matter how tight your lid is, everything in the shop will rust.

Ask me how I know...

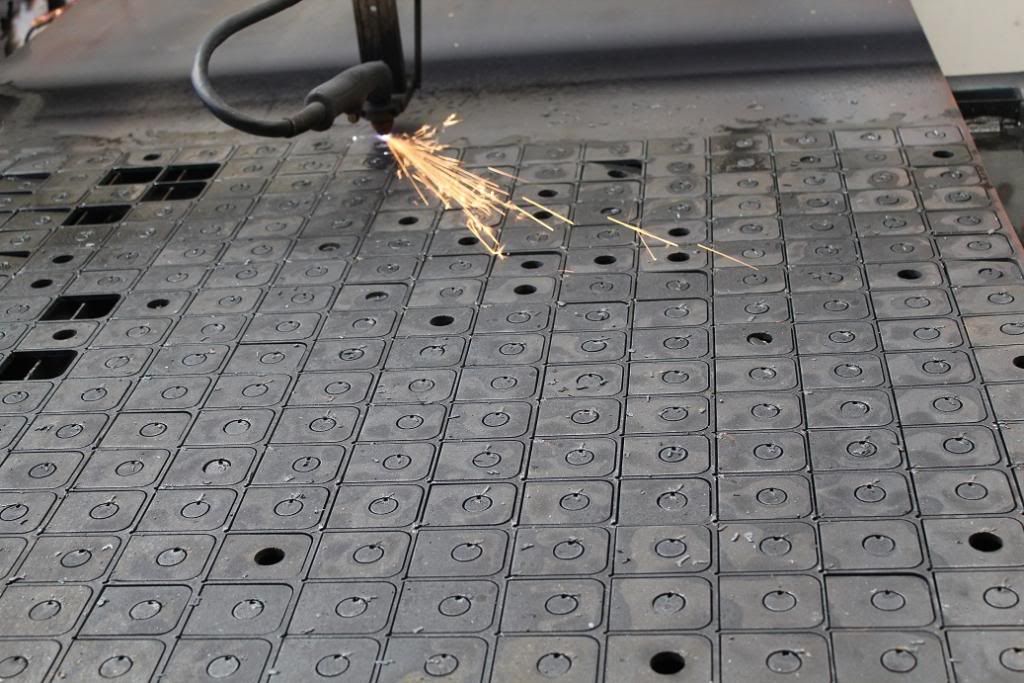

The PlasmaCam was dialed in pretty well but there are always a few places that will have that stubborn little booger of dross. A knotted cup brush does a pretty decent job but leaves a little lip that would lead to edge pull with the powder coating. Ever try to find metal paper clips? Everything is plastic now. Finally, I came across some brass ones and daisy-chained the pieces six at a time for coating and curing.

Staged for coating;

I got $4.75/ea., powder coated with single stage (Rust). It was gummert money.

You currently do not have access to download this file.

To gain download access for DXF, SVG & other files Click Here

Dano Roberts

droberts@ironpequod.com

PlasmaCam DHC-2 v3.11

Hypertherm PowerMax-30

Serving Laramie, Wy since Thursday

droberts@ironpequod.com

PlasmaCam DHC-2 v3.11

Hypertherm PowerMax-30

Serving Laramie, Wy since Thursday

-

muzza

- 4 Star Member

- Posts: 1472

- Joined: Wed Feb 04, 2009 5:35 pm

Re: Cleanup & Packaging of Hundreds of Cut Items

Had a job recently where a customer wanted 420 lugs cut from 1/4 inch. Each lug being about 2 1/2 x 2 with a 3/4 hole.

I cut on a water table so to make life easier I left a small bit attached on a corner, a few dropped through but most stayed, after cutting I droped the piece on the floor and most fell out, those that didn't I just tapped and they fell out.

I then used a shovel to scoop them up and into the cement mixer for about 15 - 20 minutes, yep it was noisy so I went inside and made a cuppa.

When they were done I stacked them all in a cardboard box that was originally a bearing box so was pretty sturdy but bloody heavy. They all came out with that clean tumbled look and it cleaned the drum of the mixer up nicely too.

Hourly rate worked out pretty high, I don't really like multiple quantity type jobs so I quoted it high and he never hesitated.

Murray

I cut on a water table so to make life easier I left a small bit attached on a corner, a few dropped through but most stayed, after cutting I droped the piece on the floor and most fell out, those that didn't I just tapped and they fell out.

I then used a shovel to scoop them up and into the cement mixer for about 15 - 20 minutes, yep it was noisy so I went inside and made a cuppa.

When they were done I stacked them all in a cardboard box that was originally a bearing box so was pretty sturdy but bloody heavy. They all came out with that clean tumbled look and it cleaned the drum of the mixer up nicely too.

Hourly rate worked out pretty high, I don't really like multiple quantity type jobs so I quoted it high and he never hesitated.

Murray

-

beefy

- 4.5 Star Member

- Posts: 1504

- Joined: Fri Jan 18, 2013 3:19 am

Re: Cleanup & Packaging of Hundreds of Cut Items

Thanks again for your input guys, I'm soaking up everything you say.

I picked up a 450mm diameter steel pipe about 700mm long a while back. It was going to be use for a special tube auger design I've conjured up, but now I think it will get made into a tumbler. I've even got a gear reduction motor I picked up with a sprocket on the shaft. Everyone talks about the terrible din from tumblers so I might see if I can line it with old car tyres or something. I've got the curse of being in a nice quiet court, and my excavation business is making my property look like a machine yard. Excavator, bobcat, trailers, augers, breaker, buckets, tyres, spare track. I'm even scared to operate my plasma table for any length of time because of the noise. I'm hoping that when I get the water tray installed it will quieten down the cutting noise (what do you reckon).

Damn I can't see so many obvious solutions. I frequent a bearing shop so I'm sure the guys would be happy to get rid of some of their heavy duty packaging boxes. Think I'll call them in the morning.

I'm surprised at some of the prices you guys manage to get. Maybe I've just been spending too much in this excavation game and earning too little that I can't relate to getting reasonable money for this service cutting game. Are the examples in this thread typical or better than normal (please say typical LOL). Don't know what gummert money is Dano but I take it that it means easy money.

Murray I haven't had the experience but I would have thought multi-part nested jobs were the cream. One item, nested to minimise material waste, cut out hundreds of times. I would have thought individual parts had a bad time to income ratio. What am I not seeing.

Keith.

I picked up a 450mm diameter steel pipe about 700mm long a while back. It was going to be use for a special tube auger design I've conjured up, but now I think it will get made into a tumbler. I've even got a gear reduction motor I picked up with a sprocket on the shaft. Everyone talks about the terrible din from tumblers so I might see if I can line it with old car tyres or something. I've got the curse of being in a nice quiet court, and my excavation business is making my property look like a machine yard. Excavator, bobcat, trailers, augers, breaker, buckets, tyres, spare track. I'm even scared to operate my plasma table for any length of time because of the noise. I'm hoping that when I get the water tray installed it will quieten down the cutting noise (what do you reckon).

Damn I can't see so many obvious solutions. I frequent a bearing shop so I'm sure the guys would be happy to get rid of some of their heavy duty packaging boxes. Think I'll call them in the morning.

I'm surprised at some of the prices you guys manage to get. Maybe I've just been spending too much in this excavation game and earning too little that I can't relate to getting reasonable money for this service cutting game. Are the examples in this thread typical or better than normal (please say typical LOL). Don't know what gummert money is Dano but I take it that it means easy money.

Murray I haven't had the experience but I would have thought multi-part nested jobs were the cream. One item, nested to minimise material waste, cut out hundreds of times. I would have thought individual parts had a bad time to income ratio. What am I not seeing.

Keith.

2500 x 1500 water table

Powermax 1250 & Duramax torch (because of the new $$$$ync system, will buy Thermal Dynamics next)

LinuxCNC

Sheetcam

Alibre Design 3D solid modelling

Coreldraw 2019

Powermax 1250 & Duramax torch (because of the new $$$$ync system, will buy Thermal Dynamics next)

LinuxCNC

Sheetcam

Alibre Design 3D solid modelling

Coreldraw 2019

- AnotherDano

- 4 Star Member

- Posts: 806

- Joined: Fri Dec 18, 2009 11:52 pm

- Location: Laramie, Wyoming

- Contact:

Re: Cleanup & Packaging of Hundreds of Cut Items

Keith,

Gummert money is slang for Government Money. The folks with the checkbook aren't spend their own money, so they are a bit more liberal with the numbers that go on the checks.

Gummert money is slang for Government Money. The folks with the checkbook aren't spend their own money, so they are a bit more liberal with the numbers that go on the checks.

Dano Roberts

droberts@ironpequod.com

PlasmaCam DHC-2 v3.11

Hypertherm PowerMax-30

Serving Laramie, Wy since Thursday

droberts@ironpequod.com

PlasmaCam DHC-2 v3.11

Hypertherm PowerMax-30

Serving Laramie, Wy since Thursday

- Gamelord

- 4.5 Star Member

- Posts: 1637

- Joined: Wed Aug 29, 2012 5:17 pm

- Contact:

Re: Cleanup & Packaging of Hundreds of Cut Items

That's a great idea to leave a little tab to hold the part into the metal. Just twist it out after grinding the dross off and then tap the tits onto a grinder to smooth it out. Never thought of that and will have to do that on the next production job where finishing isn't needed.

I use two plastic 32 gallon garbage cans for my muriatic acid - one filled with soda water for rinsing. There is zero noticeable odor and the lid seals it tight. I have a 5 gallon plastic bucket that I drilled tons of holes in, place the small parts into the bucket, then drop it into the garbage can to soak, then put the lid on. This works for all the pieces that will fit into the garbage can, larger pieces are a bit tougher. After using the acid, I would have a very hard time going back to the old ways. It makes cleanup so much easier and faster, gets rid of all mill scale, left over dross that doesn't get cleaned off by the acid usually gets blown off with compressed air. What stays takes just a few seconds with a flap disk to knock it off. For finished products, the acid also makes sand blasting time a breeze. 15 seconds a part compared to 2-3 minutes a part when not acid dipped (obviously depending on the size of the parts).

I use two plastic 32 gallon garbage cans for my muriatic acid - one filled with soda water for rinsing. There is zero noticeable odor and the lid seals it tight. I have a 5 gallon plastic bucket that I drilled tons of holes in, place the small parts into the bucket, then drop it into the garbage can to soak, then put the lid on. This works for all the pieces that will fit into the garbage can, larger pieces are a bit tougher. After using the acid, I would have a very hard time going back to the old ways. It makes cleanup so much easier and faster, gets rid of all mill scale, left over dross that doesn't get cleaned off by the acid usually gets blown off with compressed air. What stays takes just a few seconds with a flap disk to knock it off. For finished products, the acid also makes sand blasting time a breeze. 15 seconds a part compared to 2-3 minutes a part when not acid dipped (obviously depending on the size of the parts).

Once you take flight, your eyes will forever be turned to the sky." "Lack of appreciation is the worlds biggest crime."

Torchmate 6x14 w/THC Downdraft

Thermal Dynamics Cutmaster 101

Corel Draw / Adobe Illustrator

Torchmate CAD

Torchmate 6x14 w/THC Downdraft

Thermal Dynamics Cutmaster 101

Corel Draw / Adobe Illustrator

Torchmate CAD

-

muzza

- 4 Star Member

- Posts: 1472

- Joined: Wed Feb 04, 2009 5:35 pm

Re: Cleanup & Packaging of Hundreds of Cut Items

Your right really Keith, it probably is the cream dollars wise just a bit boring. I'd rather be doing something different all the time but that's just me.beefy wrote: Murray I haven't had the experience but I would have thought multi-part nested jobs were the cream. One item, nested to minimise material waste, cut out hundreds of times. I would have thought individual parts had a bad time to income ratio. What am I not seeing.

Keith.

Murray

-

beefy

- 4.5 Star Member

- Posts: 1504

- Joined: Fri Jan 18, 2013 3:19 am

Re: Cleanup & Packaging of Hundreds of Cut Items

Cheers Lads,

this thread is quite exciting for me, I'm picking up some good tips, and I've learnt some slang (gummert).

Just an addition to the tabbing idea. Could you bridge cut a few parts instead of tab cutting them. I use Sheetcam which doesn't do bridge cutting so I just "diy" the bridging in Coreldraw by welding a line through them. Thicken the line to make the bridge wider. Minimises stops and pierces like you get when tabbing in the cut path, which also creates pierce divots along the cut edge, at least with Sheetcam which doesn't do leadins on tabs.

Gamelord I've got some round plastic chemical containers I was going to use as water tanks, but now the water tanks can wait. Sometimes I think I must be thick, there's solutions in my own back yard and I get locked into another way of thinking. I was thinking a flat acid bath but your method is easier, quicker, safer and takes up less floor space. Thankyou for mentioning it.

Murray glad to here that about nesting jobs. I've been in a financial craphole since starting this excavation business and every spare cent I've got has went into paying for my backyard machine shop and cnc table build. I'd actually have some demented crazy smile on my face if I was making money with a nested cut LOL.

Keith.

this thread is quite exciting for me, I'm picking up some good tips, and I've learnt some slang (gummert).

Just an addition to the tabbing idea. Could you bridge cut a few parts instead of tab cutting them. I use Sheetcam which doesn't do bridge cutting so I just "diy" the bridging in Coreldraw by welding a line through them. Thicken the line to make the bridge wider. Minimises stops and pierces like you get when tabbing in the cut path, which also creates pierce divots along the cut edge, at least with Sheetcam which doesn't do leadins on tabs.

Gamelord I've got some round plastic chemical containers I was going to use as water tanks, but now the water tanks can wait. Sometimes I think I must be thick, there's solutions in my own back yard and I get locked into another way of thinking. I was thinking a flat acid bath but your method is easier, quicker, safer and takes up less floor space. Thankyou for mentioning it.

Murray glad to here that about nesting jobs. I've been in a financial craphole since starting this excavation business and every spare cent I've got has went into paying for my backyard machine shop and cnc table build. I'd actually have some demented crazy smile on my face if I was making money with a nested cut LOL.

Keith.

2500 x 1500 water table

Powermax 1250 & Duramax torch (because of the new $$$$ync system, will buy Thermal Dynamics next)

LinuxCNC

Sheetcam

Alibre Design 3D solid modelling

Coreldraw 2019

Powermax 1250 & Duramax torch (because of the new $$$$ync system, will buy Thermal Dynamics next)

LinuxCNC

Sheetcam

Alibre Design 3D solid modelling

Coreldraw 2019

-

squeaksman

- 1/2 Star Member

- Posts: 2

- Joined: Tue Jan 04, 2011 9:19 am

Re: Cleanup & Packaging of Hundreds of Cut Items

I have to ask where you got the "f*** it" sign in your first picture? That's awesome.

- AnotherDano

- 4 Star Member

- Posts: 806

- Joined: Fri Dec 18, 2009 11:52 pm

- Location: Laramie, Wyoming

- Contact:

Re: Cleanup & Packaging of Hundreds of Cut Items

squeaksman wrote:I have to ask where you got the "f*** it" sign in your first picture? That's awesome.

I got it here at the Spider.

It was dutifully removed by our Admin after someone complained about it being not so family friendly.

I don't disagree with either action and fully support out Admin and the decison he made.

As for the picture above, I should have taken another picture without the sign. Just an oversite. If it offends, I'll remove the picture.

Dano

Dano Roberts

droberts@ironpequod.com

PlasmaCam DHC-2 v3.11

Hypertherm PowerMax-30

Serving Laramie, Wy since Thursday

droberts@ironpequod.com

PlasmaCam DHC-2 v3.11

Hypertherm PowerMax-30

Serving Laramie, Wy since Thursday