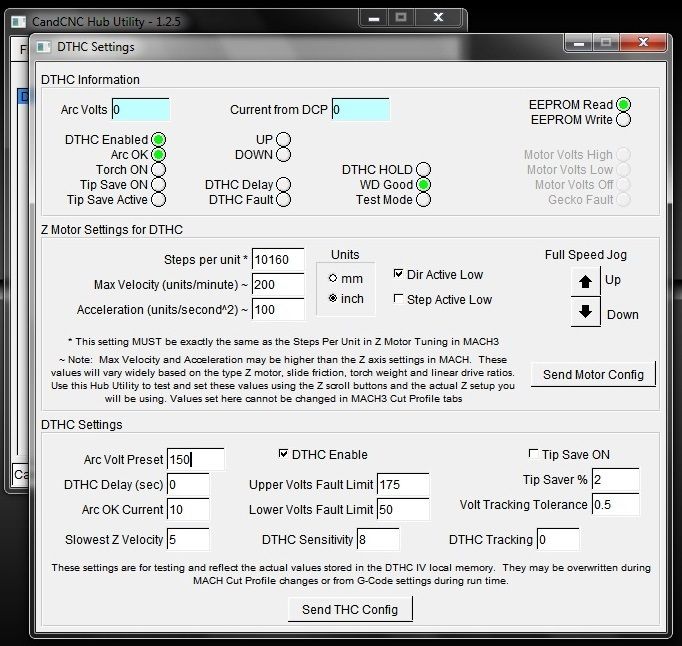

It seems to be locked on the CandCNC hub setting. I'm still quite new at this but I thought the S379 code should override the hub and set Mach to 79V.

Another odd anomaly I am having is sometimes the S10 does not turn off the DTHC at the start? As you can see in the screenshot taken after I ran the first section of the program posted below. Maybe the problems are related?

N0010 (Filename: 8in line.tap)

N0020 (Post processor: DTHC-HYT-TAP_SoftPierce+Marker-rev11J.scpost)

N0030 (Date: 13/03/2016)

N0040 G20 (Units: Inches)

N0050 F1

N0060 G53 G90 G40

N0070 (Part: 8in line)

N0080 (Operation: No Offset, Unnamed Level 1, T5: Fine Cut-Mild-Steel-16ga)

N0090 (DTHC has been disabled in this tool)

N0100(Preset Volts: 79) (Preset AMPS: 40)

N0110 ( Air Pressure Preset: 75)

N0120 ( Soft Pierce : 60 percent )

N0130 (This code for use with Ether-Cut upgrade 12-19-14 or later)

N0140( Suggested Tip Size: 45 ) ( DTHC Delay: 3 sec )

N0150 ( Min Cut Length for DTHC ON : 1 units )

N0160 S900

N0170 S10 (DTHC ON/OFF is run by rules)

N0180 S379 (Preset Volts set to 79 Volts)

N0190 S440

N0200 S875 (Set Air Pressure to 75 PSI)

N0210 S530 (DTHC Delay set to 3 Seconds)

N0220 S711 (DTHCIV tuning set to level 1)

N0230 S701 (Clear S Register)

N0240 M00

N0250(Paused: Check the DTHC Settings Hit RUN to continue)

Hub setting. Note I did change the voltage to 150V from the previous 153V before this screenshot.

Download DXF/SVG

Download DXF/SVG