Shaking Table slats

-

TMC

- 2 Star Member

- Posts: 53

- Joined: Fri Apr 11, 2014 11:54 am

Shaking Table slats

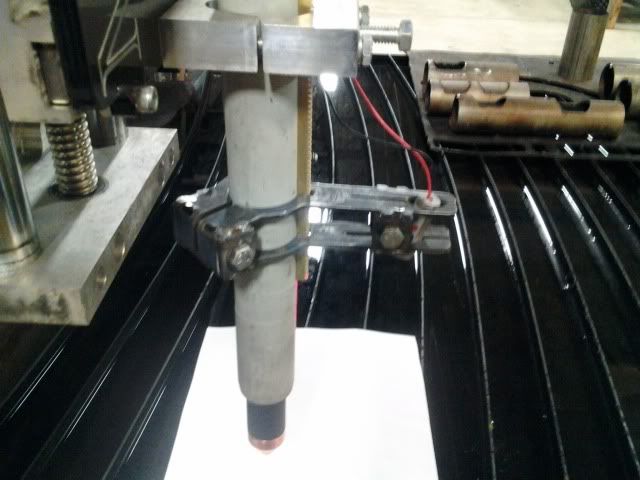

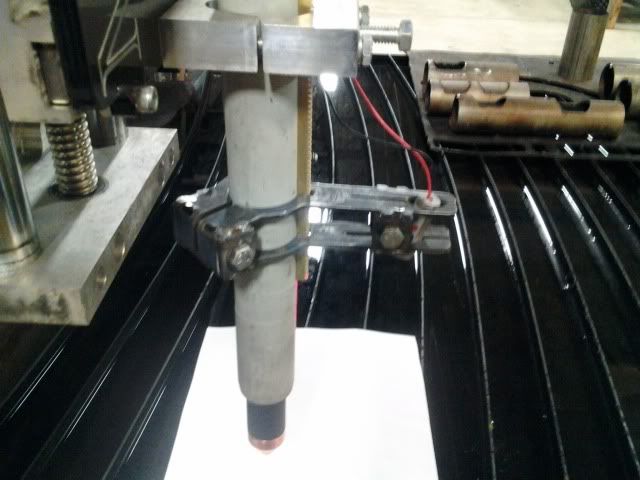

I have a water tray on my SuperB. It's a water tray built by Dynatorch. I have been chasing unacceptable squiggles in my thinner material (1/8" and less) when cutting after the the machine makes a sharp turn in a corner. The squiggle shows for about 3/16" then straightens out. Fighting with this since the table was new in August, I think I finally just realized it's being caused by my slats shaking on the table.

Have any other Dynatorch operators have this similar problem and if so what have you done to improve it?

By the way I love working with my Dynatorch and Am really glad I went with them! I'm starting to feel like I'm finally getting her dialed in.

Have any other Dynatorch operators have this similar problem and if so what have you done to improve it?

By the way I love working with my Dynatorch and Am really glad I went with them! I'm starting to feel like I'm finally getting her dialed in.

Talbot Metal Crafting

DynaTorch 4x4 SuperB

Hypertherm PMX 85

Corel 7X

Solid Edge

SheetCam

Easton, Maryland

DynaTorch 4x4 SuperB

Hypertherm PMX 85

Corel 7X

Solid Edge

SheetCam

Easton, Maryland

- WyoGreen

- 4 Star Member

- Posts: 896

- Joined: Tue Mar 04, 2014 8:36 pm

- Location: Cheyenne, Wyoming

Re: Shaking Table slats

While I don't have a dynatorch, I do have a water table with slats. I have 3 slat holders in the bottom of the tray, one at each end and one in the middle. When I install my slats in the holders slots, I offset the slats in the middle holder slots by a slot or two. This makes the slats "C" shaped, with the tension of being offset keeping the slats from shaking.

Hope that all makes some sense, Steve

Hope that all makes some sense, Steve

Precision Plasma gantry

CommandCNC Linux controller w/Feather Touch & PN200 hand controller

HT-45 plasma cutter

Plate Marker

Router

Laser

CommandCNC Linux controller w/Feather Touch & PN200 hand controller

HT-45 plasma cutter

Plate Marker

Router

Laser

- CNCCAJUN

- 4 Star Member

- Posts: 1103

- Joined: Mon Dec 26, 2011 11:38 pm

- Location: Baton Rouge, LA

Re: Shaking Table slats

Unlike a downdraft table where the slats become a part of the table, with a water table you want to do as Steve above suggested & also make sure your slats as a unit or tied to the tray. . . The other part is make sure the tray is also secured to the table base . . . and make sure the table is secured to the floor . . . at least laterally . . .

When I first got my table I was a little disappointed that my MAX cutting speed was 200 IPM. I learned quickly that to do artsy type stuff that anything over 150 IPM was just creating more work for me on the finishing end. Also was making my table work harder for zero gain.

Does this happen when you run 150 IPM?

That superB will run as fast or faster than a PlasmaCAM.

With Plasma tables you have choices. Pick (2)

SPEED

ACCURACY

PRICE Our price range!

The HYPERTHERM LOW SPEED CUT CHARTS ARE YOUR FRIEND ! ! !

Steve

When I first got my table I was a little disappointed that my MAX cutting speed was 200 IPM. I learned quickly that to do artsy type stuff that anything over 150 IPM was just creating more work for me on the finishing end. Also was making my table work harder for zero gain.

Does this happen when you run 150 IPM?

That superB will run as fast or faster than a PlasmaCAM.

With Plasma tables you have choices. Pick (2)

SPEED

ACCURACY

PRICE Our price range!

The HYPERTHERM LOW SPEED CUT CHARTS ARE YOUR FRIEND ! ! !

Steve

Smiling Gator Metal Works, LLC

Dynatorch 4X4 XLS

PowerMAX 85

Baton Rouge, Louisiana

Dynatorch 4X4 XLS

PowerMAX 85

Baton Rouge, Louisiana

-

illusivedf

- 2 Star Member

- Posts: 86

- Joined: Tue Apr 16, 2013 4:47 pm

- Location: Vermilion Ohio

- Contact:

Re: Shaking Table slats

My table has the slat shake as well. I have just been waiting to replace my slats (which I really should soon) and, I am going to finally put the center support to bow the slats on mine. Finally starting to make my table nice after just dealing with it for years lol.

Owner at Illusive Design & Fabrications

http://www.illusivefabrications.com

Air Ride Suspension Parts

Metal Fabrication

Dynatorch 4x8 with Hypertherm 1250

Vinyl Decals & Signs

Powder Coating

http://www.illusivefabrications.com

Air Ride Suspension Parts

Metal Fabrication

Dynatorch 4x8 with Hypertherm 1250

Vinyl Decals & Signs

Powder Coating

-

btburn

- 2.5 Star Member

- Posts: 205

- Joined: Sun Apr 20, 2014 9:38 am

Re: Shaking Table slats

I have a 4x4 super bee and I would guess that it is the higher speed creating the issues vs. the slats. Some of the recommended speeds get up there for the thinner stuff but like Steve said I run slower on the detailed stuff to get a better cut and not shake your gantry excessively.

On detailed artsy stuff I top it out at 150 just to get better detail and I deal with the extra dross as a side effect. On large straight and gentle curves I run at recommended speeds with no problems at all.

I plan on designing a different set of slats as we'll so they aren't perpendicular to each other . I'll burn my stock ones up a lot more first though.

On detailed artsy stuff I top it out at 150 just to get better detail and I deal with the extra dross as a side effect. On large straight and gentle curves I run at recommended speeds with no problems at all.

I plan on designing a different set of slats as we'll so they aren't perpendicular to each other . I'll burn my stock ones up a lot more first though.

Dynatorch 4x4 SuperBee, Powermax 65, Quincy QT-54, Snap On MM250SL, Thermal Arc Arcmaster 185, Corel Draw X7 and a messy garage.

- CNCCAJUN

- 4 Star Member

- Posts: 1103

- Joined: Mon Dec 26, 2011 11:38 pm

- Location: Baton Rouge, LA

Re: Shaking Table slats

If you play with your settings you can reduce your dross a great deal . . . speed, voltage, cut height, delay,etc.btburn wrote:I have a 4x4 super bee and I would guess that it is the higher speed creating the issues vs. the slats. Some of the recommended speeds get up there for the thinner stuff but like Steve said I run slower on the detailed stuff to get a better cut and not shake your gantry excessively.

On detailed artsy stuff I top it out at 150 just to get better detail and I deal with the extra dross as a side effect. On large straight and gentle curves I run at recommended speeds with no problems at all.

I plan on designing a different set of slats as we'll so they aren't perpendicular to each other . I'll burn my stock ones up a lot more first though.

Slow speed cut charts are all I use for gauge material . . .

Steve

Smiling Gator Metal Works, LLC

Dynatorch 4X4 XLS

PowerMAX 85

Baton Rouge, Louisiana

Dynatorch 4X4 XLS

PowerMAX 85

Baton Rouge, Louisiana

-

TMC

- 2 Star Member

- Posts: 53

- Joined: Fri Apr 11, 2014 11:54 am

Re: Shaking Table slats

it's not my cut speeds. I can see and feel the slats shaking at 120ipm and I can hear them shaking at 150ipm. I will call Dynatorch and see what feedback they have had and see what recommendations they have made.

Talbot Metal Crafting

DynaTorch 4x4 SuperB

Hypertherm PMX 85

Corel 7X

Solid Edge

SheetCam

Easton, Maryland

DynaTorch 4x4 SuperB

Hypertherm PMX 85

Corel 7X

Solid Edge

SheetCam

Easton, Maryland

- CNCCAJUN

- 4 Star Member

- Posts: 1103

- Joined: Mon Dec 26, 2011 11:38 pm

- Location: Baton Rouge, LA

Re: Shaking Table slats

Does the SuperB have a center support that forces all the slats to stay under tension?TMC wrote:it's not my cut speeds. I can see and feel the slats shaking at 120ipm and I can hear them shaking at 150ipm. I will call Dynatorch and see what feedback they have had and see what recommendations they have made.

I know my slats are tight because of that.

You want your slats to be in an arc shape.

Post a picture from a top view of your table with gantry parked.

Steve

Smiling Gator Metal Works, LLC

Dynatorch 4X4 XLS

PowerMAX 85

Baton Rouge, Louisiana

Dynatorch 4X4 XLS

PowerMAX 85

Baton Rouge, Louisiana

-

TMC

- 2 Star Member

- Posts: 53

- Joined: Fri Apr 11, 2014 11:54 am

Re: Shaking Table slats

It does have a center support however there is still quite a bit of play in the slats. I've done a few things to try to improve it however still not acceptable.

Talbot Metal Crafting

DynaTorch 4x4 SuperB

Hypertherm PMX 85

Corel 7X

Solid Edge

SheetCam

Easton, Maryland

DynaTorch 4x4 SuperB

Hypertherm PMX 85

Corel 7X

Solid Edge

SheetCam

Easton, Maryland

- CNCCAJUN

- 4 Star Member

- Posts: 1103

- Joined: Mon Dec 26, 2011 11:38 pm

- Location: Baton Rouge, LA

Re: Shaking Table slats

Does the center support cause all your slats to bow?

Steve

Steve

Smiling Gator Metal Works, LLC

Dynatorch 4X4 XLS

PowerMAX 85

Baton Rouge, Louisiana

Dynatorch 4X4 XLS

PowerMAX 85

Baton Rouge, Louisiana

-

btburn

- 2.5 Star Member

- Posts: 205

- Joined: Sun Apr 20, 2014 9:38 am

Re: Shaking Table slats

They are straight and parallel no arc or tension.CNCCAJUN wrote:Does the center support cause all your slats to bow?

Steve

Dynatorch 4x4 SuperBee, Powermax 65, Quincy QT-54, Snap On MM250SL, Thermal Arc Arcmaster 185, Corel Draw X7 and a messy garage.

- CNCCAJUN

- 4 Star Member

- Posts: 1103

- Joined: Mon Dec 26, 2011 11:38 pm

- Location: Baton Rouge, LA

Re: Shaking Table slats

btburn wrote:They are straight and parallel no arc or tension.CNCCAJUN wrote:Does the center support cause all your slats to bow?

Steve

I would cut 6" off the center piece, slide it forward, secure it, reinstall slats with centers offset.

It does not matter that you lose center support in the gantry parking area for those 6"s.. Quick fix to see if it will eliminate shaking . . .

Steve

Smiling Gator Metal Works, LLC

Dynatorch 4X4 XLS

PowerMAX 85

Baton Rouge, Louisiana

Dynatorch 4X4 XLS

PowerMAX 85

Baton Rouge, Louisiana

-

TMC

- 2 Star Member

- Posts: 53

- Joined: Fri Apr 11, 2014 11:54 am

Re: Shaking Table slats

Steve, Good Idea, I'm not sure I will get much flex without lengthening the slats though. I will see what movement I can get.

Talbot Metal Crafting

DynaTorch 4x4 SuperB

Hypertherm PMX 85

Corel 7X

Solid Edge

SheetCam

Easton, Maryland

DynaTorch 4x4 SuperB

Hypertherm PMX 85

Corel 7X

Solid Edge

SheetCam

Easton, Maryland

- _Ogre

- 3.5 Star Member

- Posts: 528

- Joined: Sun Sep 15, 2013 4:26 pm

- Location: Motown

Re: Shaking Table slats

see if you can curve your slats by using the same outer slots, but move the center to the next available slot

curved slats don't move and they prevent a straight cut from blowing the whole top of a slat off

curved slats don't move and they prevent a straight cut from blowing the whole top of a slat off

bulltear 4x8 cnc plasma table, candcnc bladerunner w/dthc, hypertherm powermax 65, sheetcam, mach3

laser cross hair for hypertherm torch http://www.plasmaspider.com/viewtopic.php?f=6&t=12508

an ogre smiley how cool!

how cool!

laser cross hair for hypertherm torch http://www.plasmaspider.com/viewtopic.php?f=6&t=12508

an ogre smiley

- CNCCAJUN

- 4 Star Member

- Posts: 1103

- Joined: Mon Dec 26, 2011 11:38 pm

- Location: Baton Rouge, LA

Re: Shaking Table slats

What he said . . . That is pretty much how my table is setup . . .

Steve

Smiling Gator Metal Works, LLC

Dynatorch 4X4 XLS

PowerMAX 85

Baton Rouge, Louisiana

Dynatorch 4X4 XLS

PowerMAX 85

Baton Rouge, Louisiana

-

MajorMetal

- 1.5 Star Member

- Posts: 28

- Joined: Mon Feb 18, 2013 9:49 am

Re: Shaking Table slats

CNCCAJUN wrote:Unlike a downdraft table where the slats become a part of the table, with a water table you want to do as Steve above suggested & also make sure your slats as a unit or tied to the tray. . . The other part is make sure the tray is also secured to the table base . . . and make sure the table is secured to the floor . . . at least laterally . . .

When I first got my table I was a little disappointed that my MAX cutting speed was 200 IPM. I learned quickly that to do artsy type stuff that anything over 150 IPM was just creating more work for me on the finishing end. Also was making my table work harder for zero gain.

Does this happen when you run 150 IPM?

That superB will run as fast or faster than a PlasmaCAM.

With Plasma tables you have choices. Pick (2)

SPEED

ACCURACY

PRICE Our price range!

The HYPERTHERM LOW SPEED CUT CHARTS ARE YOUR FRIEND ! ! !

Steve

I get these squiggly lines tho I don't believe it has anything to do with the slats. If I slow my cut speeds down on real tight spaces I am able to eliminate these squiggly lines. My slats have always been straight and I have never arched them. I may have to try that.

And where do you find the Hypertherm low speed cut chart you speak of? I agree low speed is your friend on the arty stuff.

-

MajorMetal

- 1.5 Star Member

- Posts: 28

- Joined: Mon Feb 18, 2013 9:49 am

Re: Shaking Table slats

Anybody know what happened to Steve (CNC Cajun)? I talked to him on the phone before he got his table because he wanted my opinion on Dynatorch. Sent him a PM a few months ago and never heard back. He hasn't been on here in months. Hopefully all is well for him.

-

muzza

- 4 Star Member

- Posts: 1447

- Joined: Wed Feb 04, 2009 5:35 pm

Re: Shaking Table slats

http://www.plasmaspider.com/viewtopic.p ... 6095&hilitMajorMetal wrote:Anybody know what happened to Steve (CNC Cajun)? I talked to him on the phone before he got his table because he wanted my opinion on Dynatorch. Sent him a PM a few months ago and never heard back. He hasn't been on here in months. Hopefully all is well for him.

-

TMC

- 2 Star Member

- Posts: 53

- Joined: Fri Apr 11, 2014 11:54 am

Re: Shaking Table slats

He unfortunately and unexpectedly passed away recently. He is truely missed here.

Talbot Metal Crafting

DynaTorch 4x4 SuperB

Hypertherm PMX 85

Corel 7X

Solid Edge

SheetCam

Easton, Maryland

DynaTorch 4x4 SuperB

Hypertherm PMX 85

Corel 7X

Solid Edge

SheetCam

Easton, Maryland

-

MajorMetal

- 1.5 Star Member

- Posts: 28

- Joined: Mon Feb 18, 2013 9:49 am

Re: Shaking Table slats

I was afraid that may have happened. He seemed like a great guy.

Download DXF/SVG

Download DXF/SVG